Specializing in rapid prototyping and on-demand production

Multifunctional machining firm with a robust supply chain, delivering high-quality products across diverse industries.

--Certificate : ●ISO9001:2015 ●IATF16949:2016

--All uploads are secure and confidential

Who We Are

Well Proto is a fully integrated manufacturing company specializing in CNC machining/sheet metal fabrication/tooling/molding/3D Printing. At the forefront of industry innovation, we take pride in delivering precision, quality, and efficiency through our state-of-the-art production technologies like CNC machining, 3D printing, and more

Capability

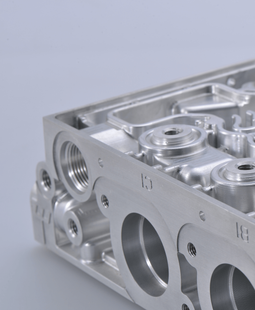

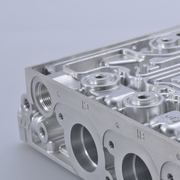

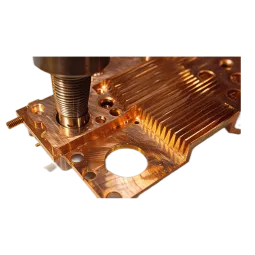

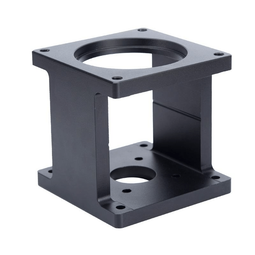

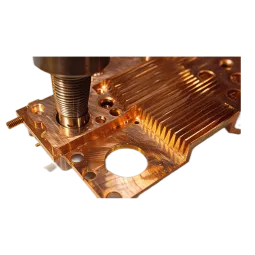

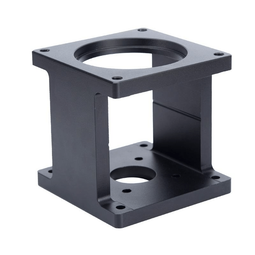

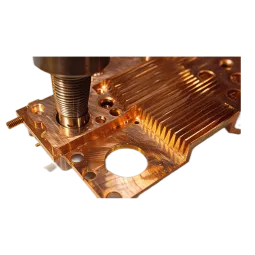

CNC Machining

Milling, turning and

post-processing

--Tolerance down to ±.008in (0.020mm)

--Lead time from 1 business day

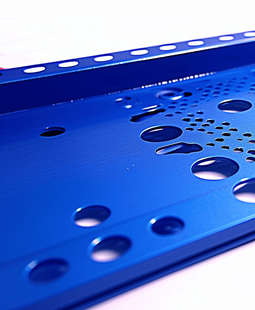

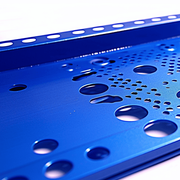

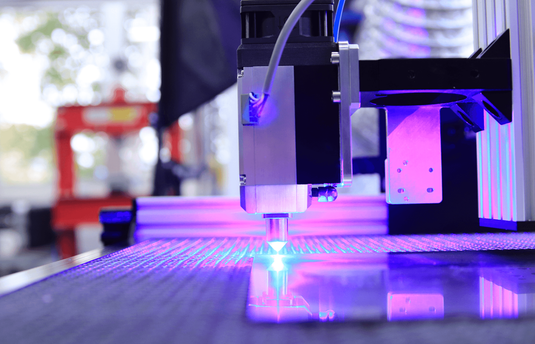

Sheet Metal

Laser cutting, bending

and stamping

--Tolerance down to±.004in

(0.1mm)

--Lead time from 1 business day

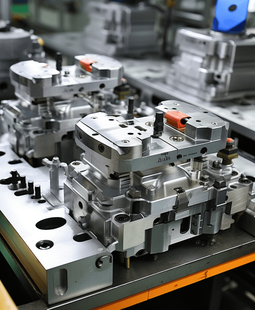

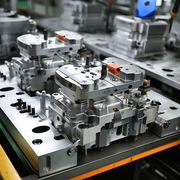

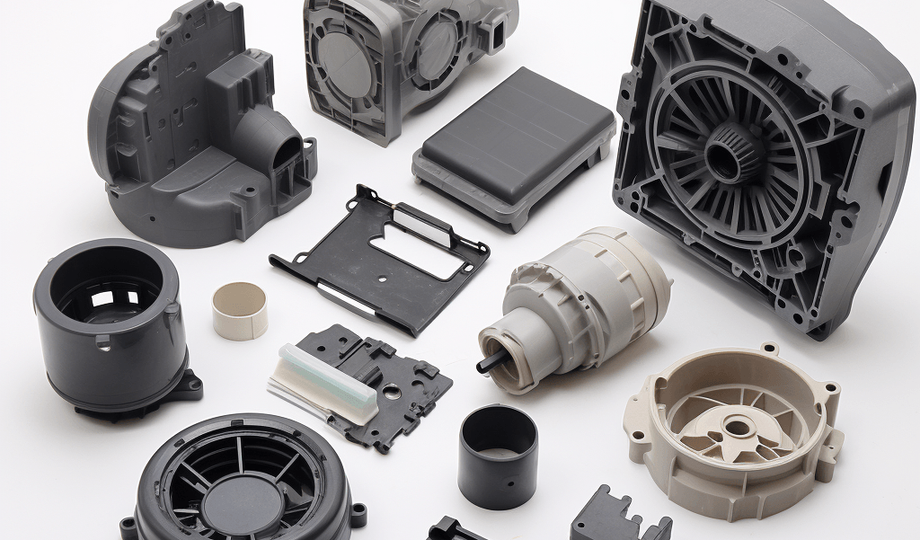

Tooling&Molding

Rapid tooling and

production tooling

--Wide range of part complexities

--1 to 1M parts

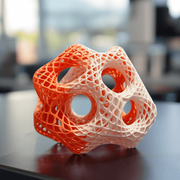

3D Printing

FDM,SKA,SLS,MJF

--±0.3% with a lower limit of ±.012in

--Lead time from 1 business day

(1)_f6db3.png)

(1)_f49ed.png)

(1)_f6db3.png)

(1)_f49ed.png)

(1)_f6db3.png)

(1)_f49ed.png)

Work with us

Upload a CAD file

Upload your 2D/3D file with requirements such as quantity, material, surface finishes, annual order quantity, etc.

Get Quote With DFM

Within a few hours, we'll send you the design for manufacturability(DFM)analysis and real-time pricing, lead time, shipping-time, ETC.

Manufacturing Begins

Once you review your quote and place your order, we'll start the manufacturing process. We also offer finishing and processing options.

Parts on the Way!

Our digital manufacturing process allows us to produce as fast as 1 day.

Our clients

Partnering with industry leaders across the globe, Well Proto earns trust through precision manufacturing, unwavering quality, and dedicated service. Your vision, machined to perfection — that’s our commitment to you.

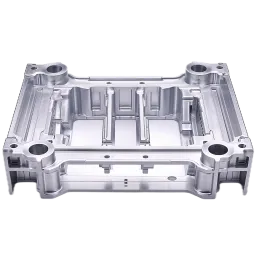

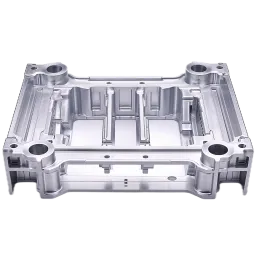

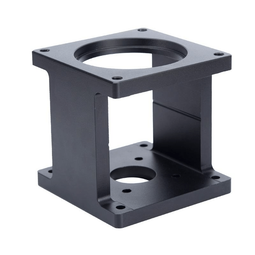

Some Cases

Aerospace Component Precision

Aerospace industry clients needed highly precise and durable components for an advanced jet propulsion system.

Our CNC machining expertise allowed us to manufacture complex parts within precise tolerances of +/- 0.005 mm, ensuring seamless integration into the client’s engineering workflow.

The project was delivered ahead of schedule, featuring materials that exceeded industry standards for durability, and our precision work led to a long-term partnership with the client.

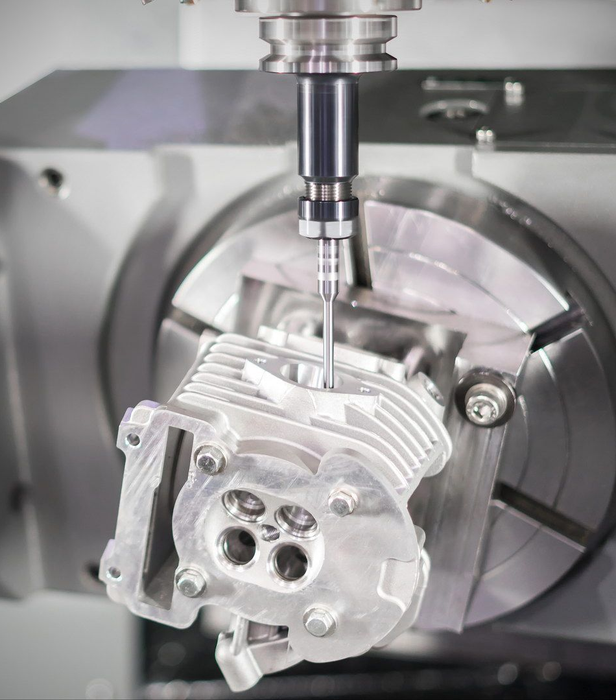

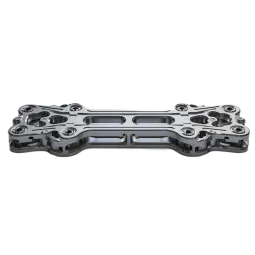

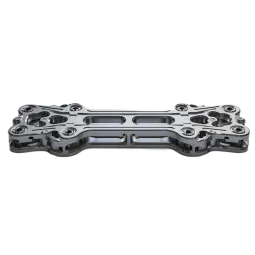

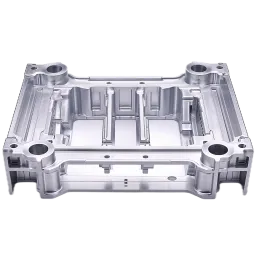

Custom Automotive Prototyping

An automotive manufacturer required rapid prototyping for custom-designed engine parts to test in their newest vehicle model.

Leveraging our efficient CNC machining processes and adaptable workflow, we produced high-quality prototypes that met strict industry specifications within a short lead time.

Our commitment to quick turnarounds and quality resulted in prototypes that expedited the client’s R&D phase, setting the stage for mass production.

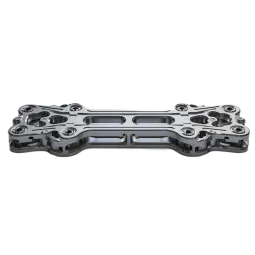

Medical Device Innovation

A medical startup needed complex surgical tools made from biocompatible materials, under rigorous standards.

With our state-of-the-art CNC machinery and meticulous quality control, we created intricate tools that adhered to strict medical regulations while maintaining optimal functionality.

Our ability to meet critical requirements and provide reliable products strengthened the client’s confidence in launching a groundbreaking medical device in the market.

Join 50,000+ businesses

Engineers at automation team

I want to express my appreciation for the outstanding support you provided with our machined parts amid our budgetary and lead-time challenges. Your help was instrumental, and I’m excited about the prospects of increasing our business with Well Proto.

Designer at robotic company

Well Proto has significantly enhanced our efficiency in securing dependable prototypes with their streamlined pricing and instantaneous quotes. Their extensive catalog of materials, complete with comprehensive datasheets, allows us to make informed decisions in selecting the optimal materials for our needs.

Purchasing manager

As a Purchasing Manager in the machinery sector, I’m impressed by Well Proto's precision and professionalism. Their high-quality CNC services, quick turnaround, and seamless communication make them a trusted partner in our supply chain.

Blogs

Reducing Manufacturing Costs with Smart CNC Solutions

Learn how smart CNC strategies can streamline production and cut costs. We’ll explore efficient software for toolpath optimization, ideal material and finish selection. Also, discover essential tips for reducing waste and refining production planning to boost your manufacturing economy.

Crafting Excellence with Custom CNC Machining

Discover how custom CNC machining fuses innovation with exactness to revolutionize design. We delve into optimizing CNC-compatible designs for top-notch performance, smart material choices, balancing design details with functionality, and streamlined DFM strategies.

Designing Custom Parts for Peak Performance and Precision

Explore the synergy of custom part design and peak performance. We focus on advanced techniques like 3D CAD modeling, stress simulation for durability, and modular design strategies to enhance functionality while ensuring manufacturability. Perfect for those seeking to lead in markets from aerospace to medical with robust, tailored solutions.

Mastering Fast-Track Production in CNC Machining

Discover key strategies for swift, high-quality CNC production. We discuss lean manufacturing, the efficiency of 5-axis CNC systems, and the advantages of rapid prototyping. Learn how a partnership with a top-notch CNC provider can deliver superior speed and precision, giving you a competitive edge.

FrequentlyFAQs

Why choose Well Proto?

Years of manufacturing experience, industry, and trade company, strict quality control from zero to one, serving more than 10,000+ customers in countries all over the world.

What materials do you machine?

We machine a variety of materials, including aluminum, stainless steel, copper, brass, titanium, various plastics, and more.

How do I make sure Well Proto's parts meet my requirements?

As a manufacturer, to ensure that the manufactured parts meet your requirements, Well Proto would:

1. Review your specifications.

2. Enforce strict quality control.

3. Adhere to relevant certifications.

4. Conduct thorough testing.

5. Keep open communication with you.

What's your production lead time?

The generation time is based on the complexity of the part, and the fastest we can do it is one day.

How long does it usually take to get the parts?

With DHL, FEDEX and other express delivery, you can get the parts in 3-5 days without any worries.

Machining

Don’t miss out on these amazing services below!