Surface Finishes

Well Proto excels in providing top-tier surface finishes, ensuring durability, enhanced aesthetics, and superior quality for your products. Our precision techniques, set your parts apart in the marketplace.

--Certificate : ●ISO9001:2015 ●IATF16949:2016

--All uploads are secure and confidential.

What is Surface Finishes?

Surface finishes refer to the final treatment or coating applied to the exterior of a material to enhance its appearance, surface quality, and characteristics such as wear resistance, corrosion resistance, reflectiveness, and mechanical properties.

The selection of a surface finish depends on the application, material, and desired end properties of the product

All our services are available for you at the moment!

(For more Surface Finishes, please consult the Well Proto team)

Grinding

Grinding is a process that uses an abrasive wheel to smooth the surface.

Polishing

Polishing the surface to achieve a reflective, high-gloss finish.

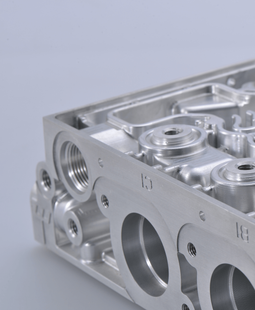

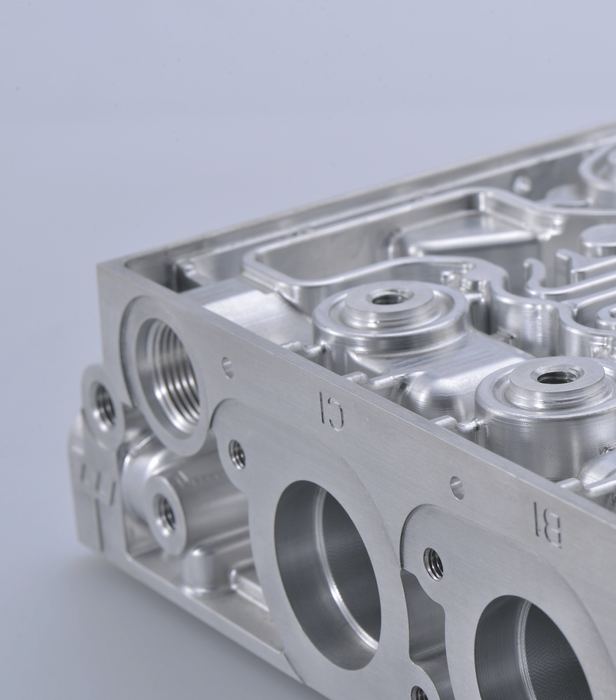

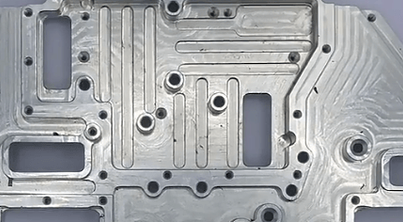

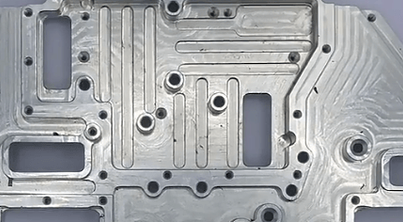

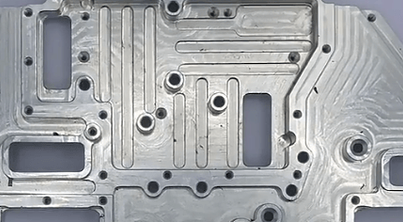

Machining

Machining marks are visible, light surface scratches are visible.

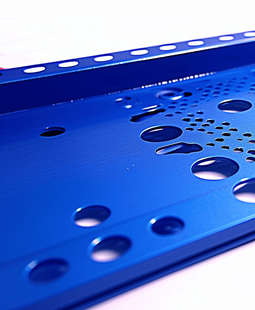

Anodizing

Using an electrolytic passivation process to increase the thickness of the natural oxide layer on the surface of metal parts.

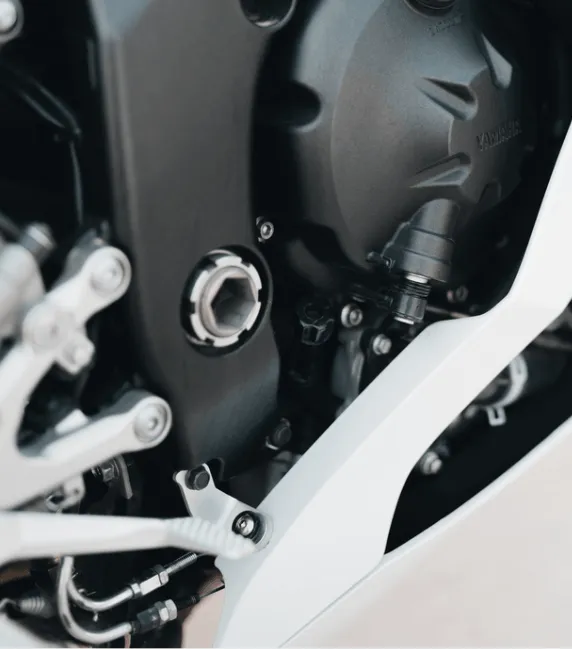

Powder Coating

Electrostatically applying dry, powdered paint and then curing it with heat.

Electroplating

Using electrical current to plate the surface with a thin layer of metal, such as chrome or nickel.

Passivation

Treating stainless steel with an acid solution to remove free iron and contaminants, promoting corrosion resistance.

Annealing

Heating the material and then cooling it to relieve internal stresses and improve machinability or ductility.

Bead Blasting

Shooting fine glass or ceramic beads at a material to create a non-directional, textured surface.

Painting

Applying a liquid paint layer for aesthetic and protective purposes.

Laser Surface Treatment

Using lasers for engraving, hardening, cladding, or changing the surface texture.

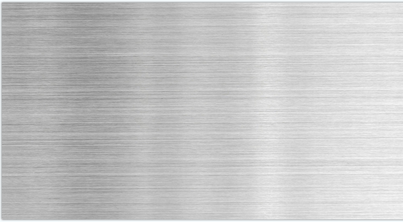

Brushing

Brushing is a technique to create fine, parallel lines on a metal surface, often used for aesthetic purposes.

Grinding

Grinding is a process that uses an abrasive wheel to smooth the surface.

Polishing

Polishing the surface to achieve a reflective, high-gloss finish.

Machining

Machining marks are visible, light surface scratches are visible.

Anodizing

Using an electrolytic passivation process to increase the thickness of the natural oxide layer on the surface of metal parts.

Powder Coating

Electrostatically applying dry, powdered paint and then curing it with heat.

Electroplating

Using electrical current to plate the surface with a thin layer of metal, such as chrome or nickel.

Passivation

Treating stainless steel with an acid solution to remove free iron and contaminants, promoting corrosion resistance.

Annealing

Heating the material and then cooling it to relieve internal stresses and improve machinability or ductility.

Bead Blasting

Shooting fine glass or ceramic beads at a material to create a non-directional, textured surface.

Painting

Applying a liquid paint layer for aesthetic and protective purposes.

Laser Surface Treatment

Using lasers for engraving, hardening, cladding, or changing the surface texture.

Brushing

Brushing is a technique to create fine, parallel lines on a metal surface, often used for aesthetic purposes.

Grinding

Grinding is a process that uses an abrasive wheel to smooth the surface.

Polishing

Polishing the surface to achieve a reflective, high-gloss finish.

Machining

Machining marks are visible, light surface scratches are visible.

Anodizing

Using an electrolytic passivation process to increase the thickness of the natural oxide layer on the surface of metal parts.

Powder Coating

Electrostatically applying dry, powdered paint and then curing it with heat.

Electroplating

Using electrical current to plate the surface with a thin layer of metal, such as chrome or nickel.

Passivation

Treating stainless steel with an acid solution to remove free iron and contaminants, promoting corrosion resistance.

Annealing

Heating the material and then cooling it to relieve internal stresses and improve machinability or ductility.

Bead Blasting

Shooting fine glass or ceramic beads at a material to create a non-directional, textured surface.

Painting

Applying a liquid paint layer for aesthetic and protective purposes.

Laser Surface Treatment

Using lasers for engraving, hardening, cladding, or changing the surface texture.

Brushing

Brushing is a technique to create fine, parallel lines on a metal surface, often used for aesthetic purposes.

FrequentlyFAQs

What surface finishing options do you offer?

At Well Proto, we offer a variety of surface finishing options, including anodizing, powder coating, brushing, polishing, electroplating, bead blasting, and painting. Our goal is to meet the diverse needs and specifications of our clients' projects

Can you recommend the best surface finish for my project?

Absolutely! Our expert team can provide recommendations based on the material, intended use, and aesthetic requirements of your project. We consider factors such as durability, corrosion resistance, and visual appeal to suggest the most suitable finish.

Will surface finishing alter the dimensions of my parts?

Some finishing processes can alter the dimensions slightly, but at Well Proto, we take great care to ensure any changes remain within the tolerances specified by the client. Our precise application methods are designed to enhance your parts while maintaining their integrity.

Can you match specific color requirements for finishes?

Yes, we can match specific colors for certain finishing types such as powder coating and painting. You can provide us with a RAL or Pantone code, and we will ensure your product has the exact color you're looking for.

What types of materials can you apply surface finishes to?

We work with a wide range of materials, including but not limited to metals (such as aluminum, steel, and brass), plastics, and composites. Each material has recommended finishes that can enhance its properties, and we can advise on the best choices for your particular application.

Don’t miss out on these amazing services below!