Material

Well Proto promises that all materials comply with European and American standards, RoHS standards and provide material certificates.

--Certificate : ●ISO9001:2015 ●IATF16949:2016

--All uploads are secure and confidential

A wide range of materials for manufacturing, with applications in multiple industries. Ideal for both one-off prototypes and end-use custom parts.

(For more materials, please consult the Well Proto team)

- Metal

- Plastic

Aluminum

It is widely used in many industries as well as for general purposes. It has good weldability, good corrosion resistance, processability and mechanical properties. It is one of the most common extrusion alloys, but its mechanical properties make it ideal for many other applications.

Processing: CNC Machining; Sheet Metal Fabrication; 3D Printing

Surface Finishes: Brushing; Bead blasting; Grinding; Anodizing; Electroplating; Powder Coating.

Application industries: Automobiles; Ships; Electrical equipment.

Stainless Steel

It is capable of achieving a wide range of strength and toughness, depending on the precipitation or aging temperature during hardening. The steel of choice for engineers and designers, it has high strength, good corrosion resistance and toughness.

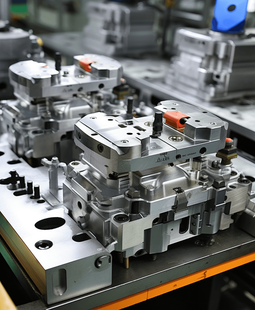

Processing: CNC Machining; Sheet Metal Fabrication; Tooling&Molding.

Surface Finishes: Brushing; Bead blasting; Grinding; Passivation; Electroplating; Powder coating; Painting.

Application industries: Aviation; Chemical equipment; Refining equipment.

Steel

It can reach higher strength levels through heat treatment while maintaining good toughness, impact properties, wear resistance and fatigue strength levels, as well as good atmospheric corrosion resistance.

Processing: CNC Machining; Tooling&Molding.

Surface Finishes: Brushing; Bead blasting; Grinding; Annealing; Electroplating.

Application industries: Engineering components; Connecting rods; Bolts.

Brass

Brass is a highly workable alloy with good tensile strength and natural corrosion resistance. Ideal for parts requiring low friction. The proportions of copper and zinc can be varied to produce different types of brass, which affects its strength and ductility.

Processing: CNC Machining.

Surface Finishes: Brushing; Bead blasting; Grinding; Electroplating.

Application industries: Faucet accessories, Fasteners.

Titanium

Titanium alloys are known for their high strength, low density, excellent corrosion resistance, and stability at high temperatures. Hardening will occur during processing, poor heat dissipation, high temperature in the processed parts, and rapid wear of props.

Processing: CNC Machining; Sheet Metal Fabrication.

Surface Finishes: Brushing; Bead blasting; Grinding; Electroplating; Nitriding; Anodizing.

Application industries: Aerospace industry; Military; Biomedicine; High-performance racing.

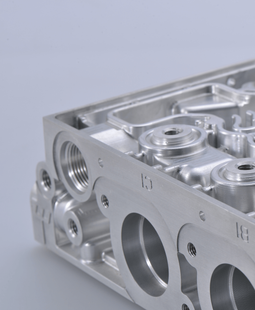

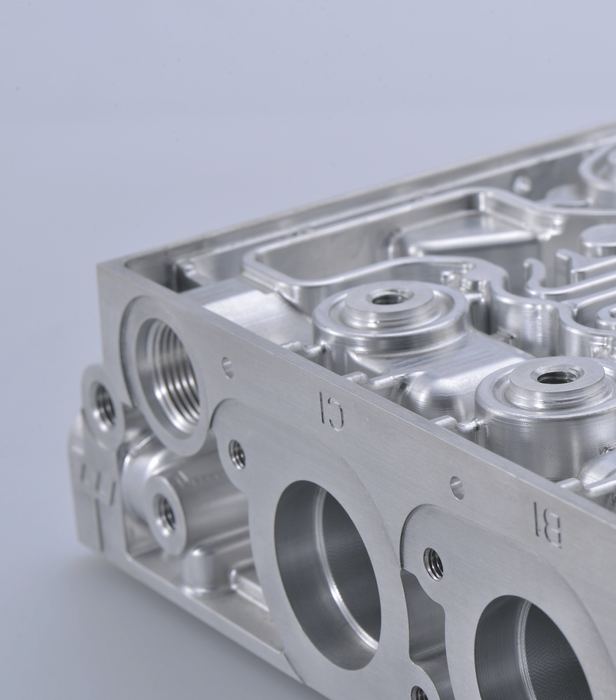

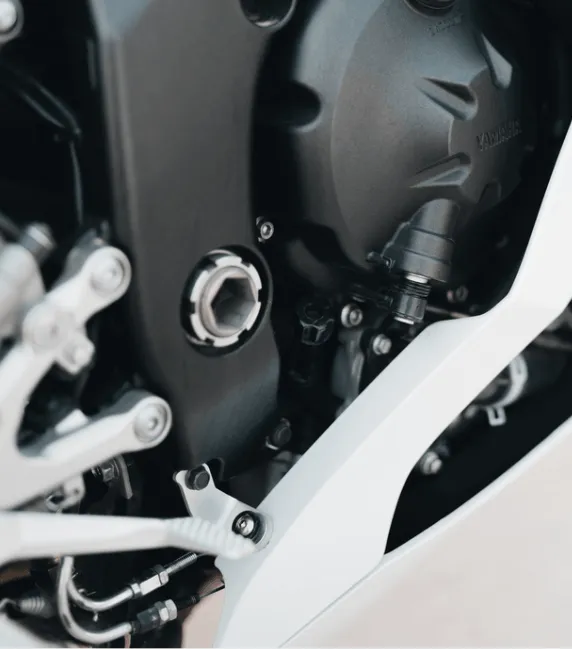

Metal Machining

Metal machining is essentially the art of transforming a raw slab of metal into a specific form or item that meets a particular design.

At Well Proto, machining is executed with the highest precision using CNC machinery, capable of turning any digital design generated via CAD into a tangible three-dimensional product.

Our adept team of machinists predominantly operates 3- and 5-axis CNC machines to manufacture metal components that successfully clear our rigorous online DFM (Design for Manufacturing) assessments.

With state-of-the-art CNC technology at Well Proto's disposal, we are capable of carving out intricate features on parts with remarkable precision, all while upholding stringent tolerance standards.

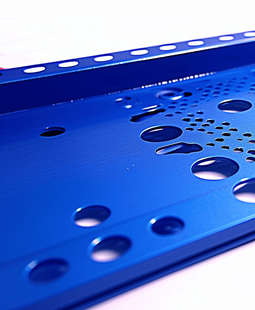

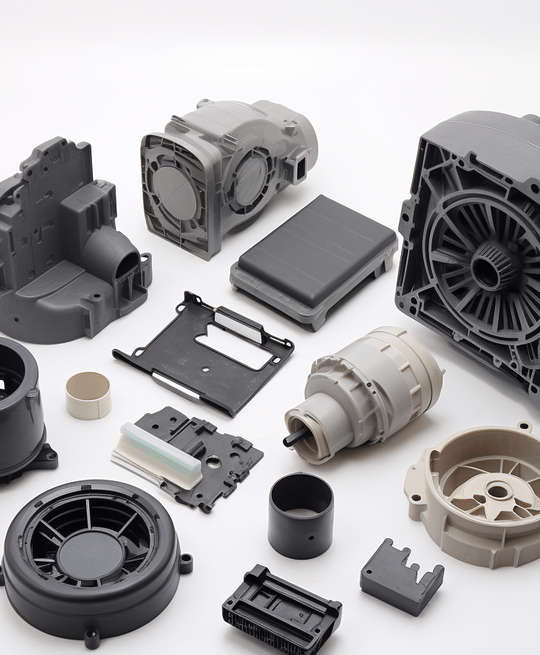

Plastic Machining

At Well Proto, we prioritize crafting lightweight, easily machined, and cost-efficient plastic parts using CNC machines.

These machines are capable of handling various types of plastics, each offering its own machining benefits and constraints.

Our advanced 3-axis, 4-axis, and 5-axis CNC equipment is designed for creating precise, high-quality plastic components with complex geometries.

For smaller production runs, our CNC machining services are more cost-effective than injection molding.

Frequently FAQs

What types of metal can you use for CNC machining and sheet metal fabrication?

We work with a wide array of metals, including aluminum, stainless steel, brass, copper, titanium, and more, offering a range of properties to suit various applications.

Can you match exact color specifications for plastic parts?

Yes, we can match exact colors by using pre-colored materials or by post-processing the parts through painting or dyeing to achieve the desired color specification.

Are your materials safe for use in food-related products?

We offer food-grade materials that comply with FDA regulations for use in kitchenware, packaging, and other food-related products.

How do you ensure material quality?

We source our materials from reputable suppliers and perform rigorous inspections to ensure they meet our high-quality standards. Certifications and material test reports are available upon request.

What are my options if I need a material that isn’t listed on your website?

If you require a specific material not listed, please contact us. We have a network of suppliers and can often source special materials to meet your project needs.