Molding&Casting

Switch to on-demand manufacturing for rapid, high-quality molded parts, with free prototyping tools upon transition. Benefit from a single supplier’s free design aid for faster production and streamlined supply chain management.

--Certificate : ●ISO9001:2015 ●IATF16949:2016

--All uploads are secure and confidential

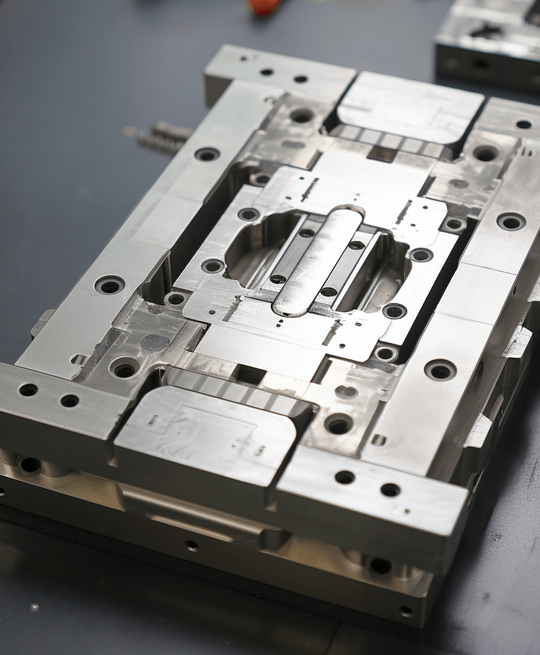

Well Proto Molding&Casting capability

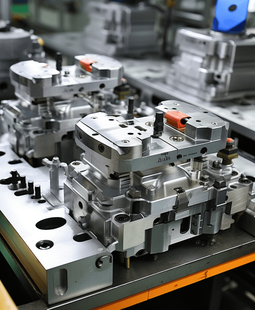

Well Proto’s team has streamlined the Molding&Casting process for quicker outcomes, offering several choices like quick injection molding, Die casting, and final production tooling. The technique of plastic injection molding involves using a hot barrel to inject plastic into a specifically engineered mold. The plastic is pushed into the mold’s cavity, left to cool and solidify, and then ejected to form a three-dimensional item. This approach can consistently shape a wide array of products with precision and speed by adjusting temperature and pressure.

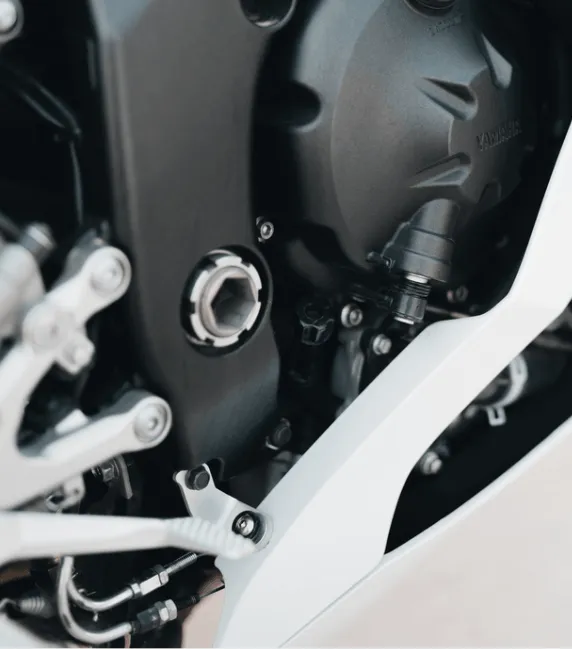

Injection Molding

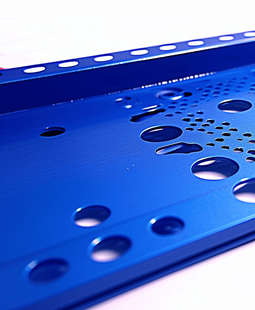

Injection molding is a widespread manufacturing process used to produce various items by melting materials and injecting them into metal molds. Once cooled, the material solidifies into the desired shape. It’s commonly used in automotive, healthcare, and consumer goods industries due to its ability to efficiently produce large volumes with precise outcomes.

The process works with many materials, including different plastics and rubber, and can be scaled for high-volume automated production or customized for smaller runs. Its versatility and design flexibility make it fundamental to modern manufacturing.

Casting

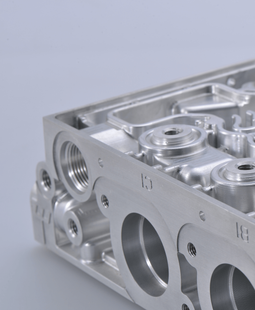

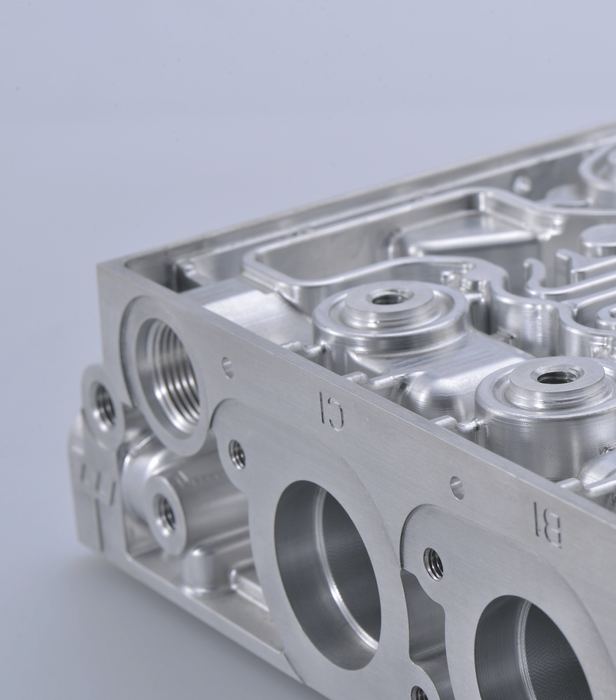

Die casting is a process ideal for producing metal parts in medium to high volumes, like injection molding for plastics. It involves high-pressure injection of molten metal into a mold, followed by cooling and ejection of the part. Excess material from the process, or gating, is trimmed off.

The method is precise, with standard tolerances starting at .005 inches and typically uses metals like aluminum, magnesium, copper, and zinc.

Available Materials for tooling&molding

Enhance your designs with our diverse selection of tool&mold mater

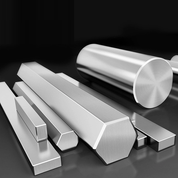

Aluminum

(Die casting)

Aluminum’s strength, lightness, thermal

properties, and corrosion resistance make it perfect for automotive components,

electronic casings, and industrial parts.

Zinc

(Die casting)

Highly ductile, impact-resistant materials

with good thermal and electrical

conductivities are ideal for crafting

precise, small parts with intricate designs.

Copper

(Die casting)

High hardness and corrosion resistance

along with excellent electrical conductivity are well-suited for applications like heat

sinks, electrical connectors, and valves.

%20-%20%E5%89%AF%E6%9C%AC_71c3d.png)

ABS

(Injection molding)

Impact-resistant and tough are ideal for

making durable products such as LEGO

bricks, automotive body parts, and

electronic housings.

Nylon

(injection molding)

Its high mechanical strength and temperature resistance, as well as good wear and abrasion

resistance, is particularly suitable for

manufacturing components like gears, bearings, and electrical insulators.

Aluminum

(Die casting)

Aluminum’s strength, lightness, thermal

properties, and corrosion resistance make it perfect for automotive components,

electronic casings, and industrial parts.

Zinc

(Die casting)

Highly ductile, impact-resistant materials

with good thermal and electrical

conductivities are ideal for crafting

precise, small parts with intricate designs.

Copper

(Die casting)

High hardness and corrosion resistance

along with excellent electrical conductivity are well-suited for applications like heat

sinks, electrical connectors, and valves.

%20-%20%E5%89%AF%E6%9C%AC_71c3d.png)

ABS

(Injection molding)

Impact-resistant and tough are ideal for

making durable products such as LEGO

bricks, automotive body parts, and

electronic housings.

Nylon

(injection molding)

Its high mechanical strength and temperature resistance, as well as good wear and abrasion

resistance, is particularly suitable for

manufacturing components like gears, bearings, and electrical insulators.

Aluminum

(Die casting)

Aluminum’s strength, lightness, thermal

properties, and corrosion resistance make it perfect for automotive components,

electronic casings, and industrial parts.

Zinc

(Die casting)

Highly ductile, impact-resistant materials

with good thermal and electrical

conductivities are ideal for crafting

precise, small parts with intricate designs.

Copper

(Die casting)

High hardness and corrosion resistance

along with excellent electrical conductivity are well-suited for applications like heat

sinks, electrical connectors, and valves.

%20-%20%E5%89%AF%E6%9C%AC_71c3d.png)

ABS

(Injection molding)

Impact-resistant and tough are ideal for

making durable products such as LEGO

bricks, automotive body parts, and

electronic housings.

Nylon

(injection molding)

Its high mechanical strength and temperature resistance, as well as good wear and abrasion

resistance, is particularly suitable for

manufacturing components like gears, bearings, and electrical insulators.

Don’t miss out on these amazing services below!