Designing Custom Parts for Peak Performance and Precision

On

21/06/2022Summary:

At Well Proto, we stand at the forefront of marrying bespoke part design with the pinnacle of operational performance. Our approach is rooted in leveraging cutting-edge technologies and methodologies to address the unique needs of industries as varied as aerospace and medical devices. By focusing on custom solutions, we ensure that every component we create meets the stringent demands for precision and robustness our clients expect.

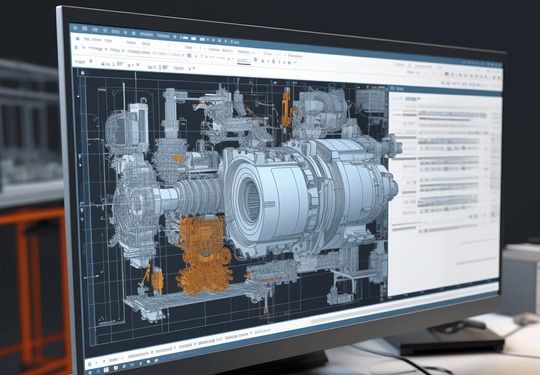

3D CAD Modeling: Crafting Parts with Precision

Drawing from the power of 3D CAD (Computer-Aided Design), we create digital blueprints that lay the foundation for manufacturing excellence.

Practical Advantages of Our 3D CAD Modeling:

- Accuracy in Design:

Our detailed models are the first step in creating parts that integrate seamlessly into specialized equipment.

- Efficient Design Process:

Adjustments to the design can be made swiftly, ensuring your project timeline stays on track.

- Clear Communication:

3D models enable clients to visualize and understand their part before it's built, aiding in transparent and effective collaboration.

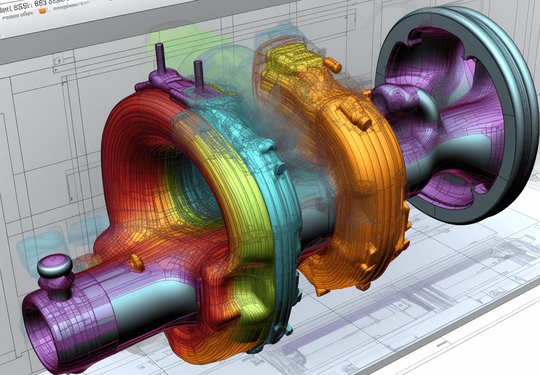

Durability Analysis Through Stress Simulation

Understanding a part's endurance under stress is crucial. We use advanced simulation to anticipate and address durability concerns.

Key Benefits of Our Stress Simulation Techniques:

- Reliability Forecasting: By pinpointing stress points before manufacturing, we avoid potential weaknesses, ensuring a durable final product.

- Material Use Efficiency: Selecting the right materials for the job is about balancing performance with cost—our simulations guide this choice.

- Lifecycle Extension: Our goal is to create parts that last. Simulating stress factors contributes to longer-lasting, more reliable parts.

Modular Design for Flexibility and Function

Our modular design approach recognizes the need for parts to be both functional and flexible, allowing easier integration into existing systems.

How Modular Design Supports Your Operations:

- Future-Ready Components: Designing for adaptability simplifies future upgrades and tech transitions.

- Simplified Maintenance: Modular design allows for quicker repairs and replacements, minimizing downtime.

- Easier Manufacturability: Considering manufacturability from the get-go ensures a seamless path from design to production.