Mastering Fast-Track Production in CNC Machining

On

04/05/2023Summary:

As a manufacturer in the machining industry, speed and precision are paramount to stay competitive. In this blog, we will explore Well Proto's approach to fast-track production in CNC machining. We will discuss the principles of lean manufacturing, the efficiency offered by 5-axis CNC systems, and the advantages of rapid prototyping. By embracing these strategies and partnering with a top-notch CNC provider like Well Proto, manufacturers can achieve superior speed, precision, and gain a competitive edge in the market.

Embracing Lean Manufacturing for Efficient CNC Production:

Lean manufacturing focuses on eliminating waste and optimizing production processes. By applying lean principles to CNC machining, manufacturers can achieve significant improvements in efficiency and productivity. Well Proto has embraced these principles by streamlining workflows, reducing setup times, and adopting just-in-time manufacturing, resulting in shorter lead times and cost savings.

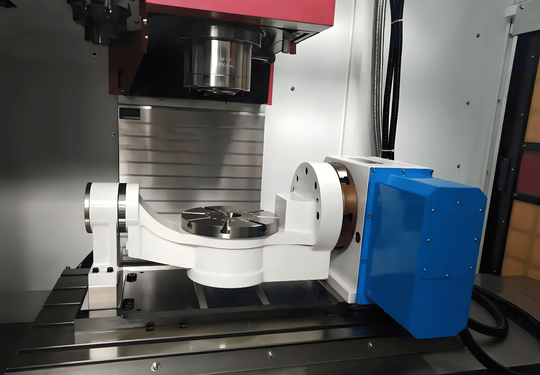

Leveraging the Efficiency of 5-Axis CNC System

The advent of 5-axis CNC systems has revolutionized the machining industry. These systems offer enhanced capabilities, allowing for complex machining operations in a single setup. Well Proto recognizes the power of these systems and has invested in state-of-the-art 5-axis CNC machines. By leveraging the additional rotational axes, Well Proto can achieve intricate cuts, smooth tool paths, and high precision, ensuring superior part quality and reducing the need for secondary operations.

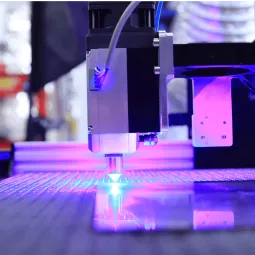

Advantages of Rapid Prototyping in CNC Machining

Rapid prototyping is a game-changer in product development, enabling manufacturers to iterate designs quickly and efficiently. Well Proto understands the importance of faster prototyping cycles, enabling clients to reduce time to market. By utilizing CNC machining for rapid prototyping, Well Proto offers clients the ability to transform CAD designs into physical prototypes swiftly. This allows for verification of form, fit, and function before proceeding to full-scale production, mitigating risks and reducing costs associated with product redesign.