Quality Control

Our relentless pursuit of excellence is evident in our robust Quality Control (QC) process. At Well Proto, we understand that the consistent delivery of high-quality products is fundamental to our reputation and the satisfaction of our customers. That’s why we’ve instituted a comprehensive QC program that permeates every stage of our workflow—from sourcing raw materials to the final delivery of our products.

Sourcing with Integrity

Quality starts at the source. We meticulously select our suppliers and institute stringent standards to ensure that all materials meet our high bar for quality. Our sourcing team works closely with vendors to audit their practices, ensuring compliance with both our internal criteria and all relevant industry regulations.

Rigorous In-House Testing

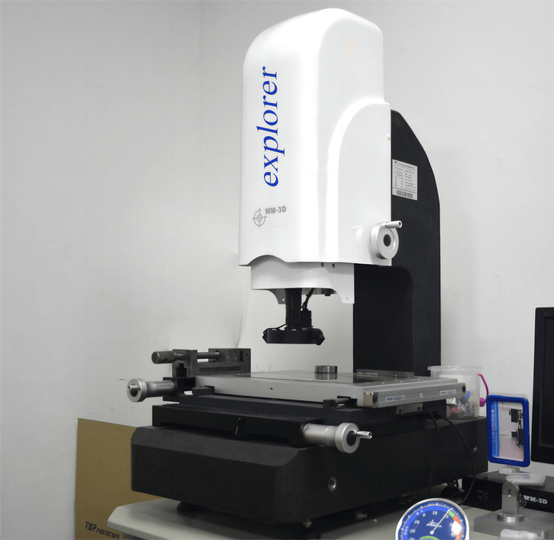

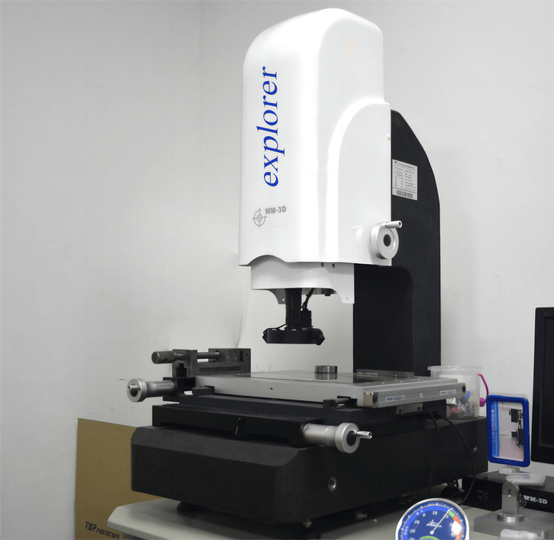

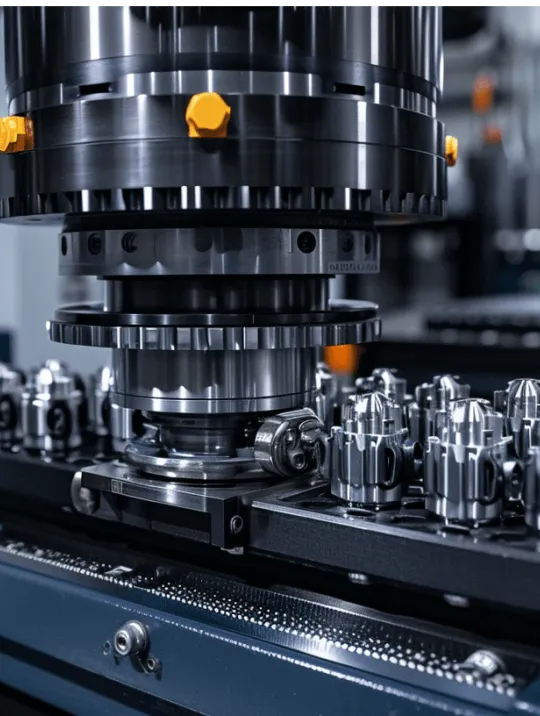

Before any product reaches our customers, it undergoes a series of rigorous tests in our state-of-the-art in-house laboratory. Our team of skilled technicians employs the latest technologies and testing methods to check for material strength, durability, and safety.

Continuous Monitoring and Improvement

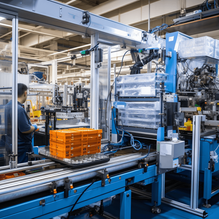

To stay ahead, our QC process includes continuous monitoring of all production lines. We leverage real-time data to make immediate adjustments, ensuring that our manufacturing process remains efficient while adhering to the highest quality standards. We also apply a program of continuous improvement, regularly reviewing our processes and making enhancements wherever possible.

Certification and Compliance

Achieving and maintaining key industry certifications is integral to our QC process. We adhere to international standards such as ISO 9001, ensuring consistent quality management throughout the company.

Customer Feedback Integration

We view our customers as vital contributors to our QC process. We actively seek out and incorporate customer feedback to fine-tune our products and services, making sure that we not only meet but exceed customer expectations.

Pre-Production Quality System

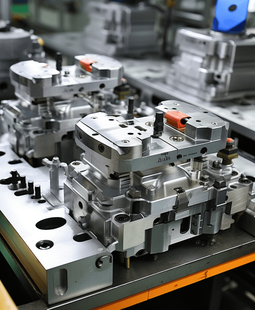

Technical Evaluation

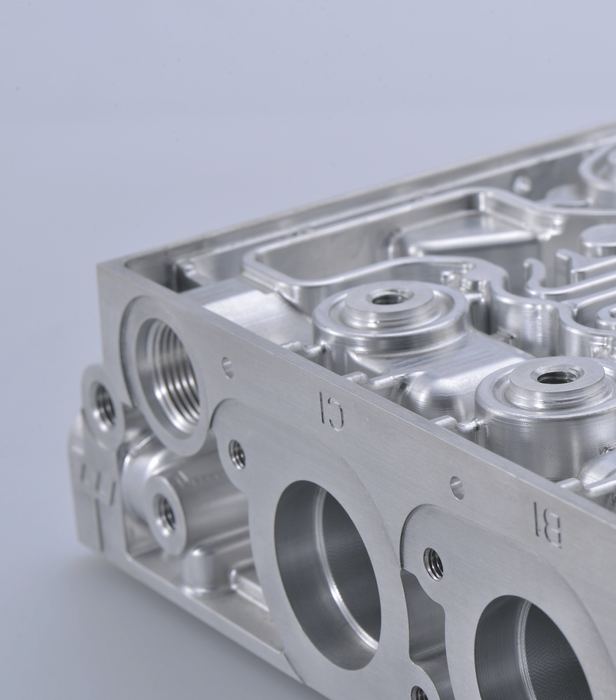

Before commencing production, the Well Proto engineering team conducts a comprehensive technical evaluation to ensure the accuracy and feasibility of your 3D and 2D drawings. This evaluation includes examining the materials, structure, processes, and other details to identify any potential mistakes or unattainable requirements right from the start.

Material Verification

At Well Proto, we provide material certification upon request. This certification is obtained from the raw material manufacturer and includes important details such as material heat number, grade, dimensions, mechanical properties, chemical analysis, and more. It offers transparency and assurance regarding the materials used in the manufacturing process.

During Production Quality Control

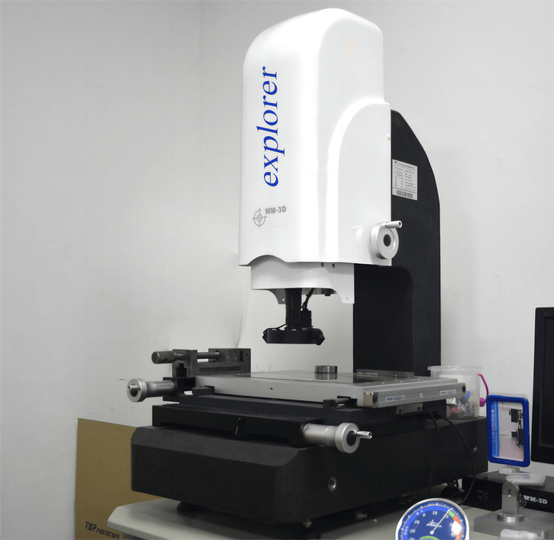

On-Site Inspection System

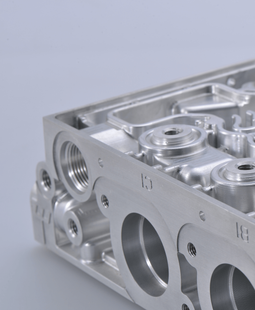

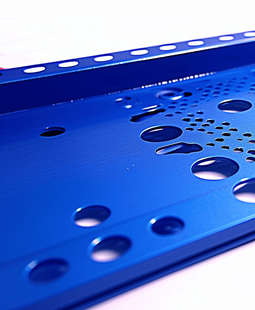

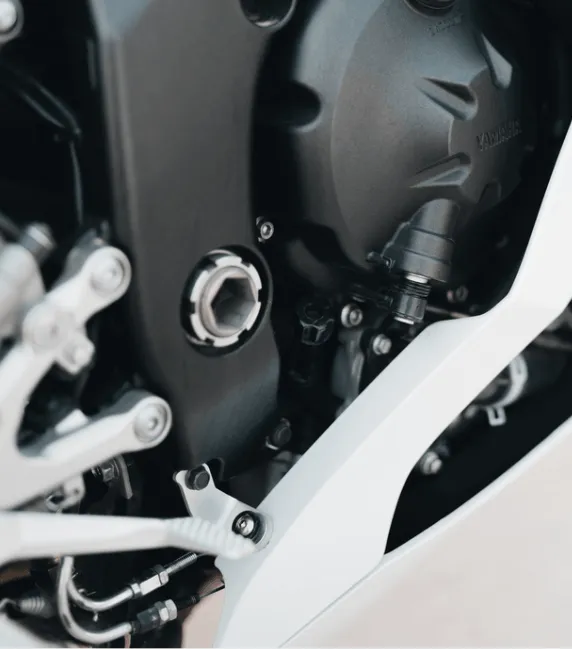

Precision machining requires precise positioning of the material block. To ensure accuracy, we have implemented an on-site inspection system where machines automatically assess and adjust the material block positions as needed. This proactive approach helps to avoid issues in the early stages of production, saving both time and costs.

In-Process Quality Control

We strictly adhere to the ISO9001:2015 requirements at Well Proto. Our dedicated quality control staff conducts routine inspections of all parts being produced every two hours. This ensures that the quality standards are consistently met throughout the production process.

First Article Inspection

To provide our customers with peace of mind before moving into mass production, we offer a first article inspection service for prototype orders. Additionally, special requests for CNC machining can be accommodated. Our team examines a sample part and provides a detailed inspection report with accompanying images. If required, we can also ship the part to you for further verification.

HAVE A QUESTION?

Contact us whenever you have any questions. We are always here for you!

Don’t miss out on these amazing services below!