Bending&Forming

Well Proto' Bending&forming offers the advantage of shaping materials into complex and precise geometries with high repeatability and efficiency.

--Certificate : ●ISO9001:2015 ●IATF16949:2016

--All uploads are secure and confidential

What is Bending?

Bending is a metal forming technique where a metal sheet, rod, tube, etc., is subjected to force to bend it to a desired angle, creating a fixed angle or curve shape.

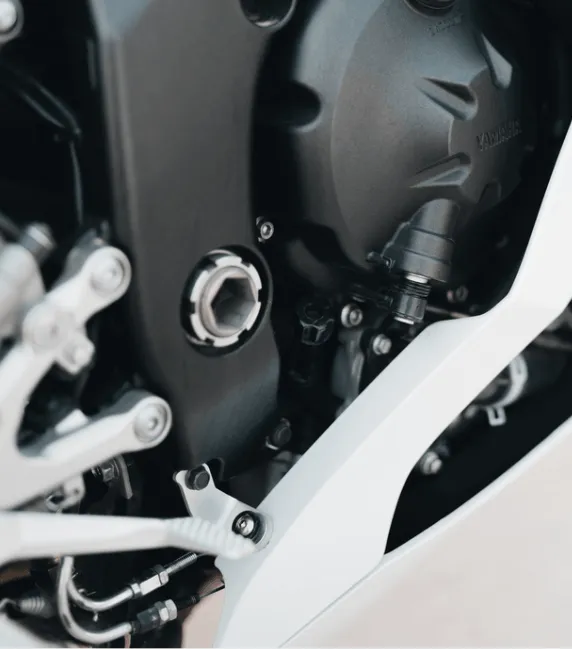

Bending can be done by various methods, including manual bending, mechanical bending, and using specialized equipment such as press brakes and bending machines.

Three Bending Types at Well Proto

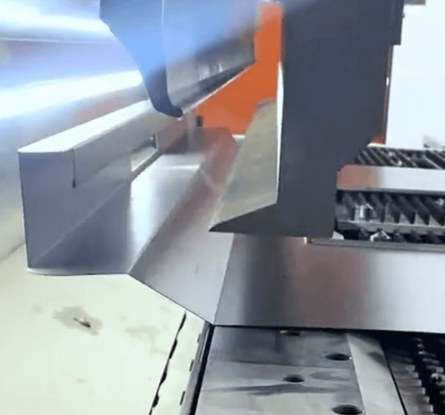

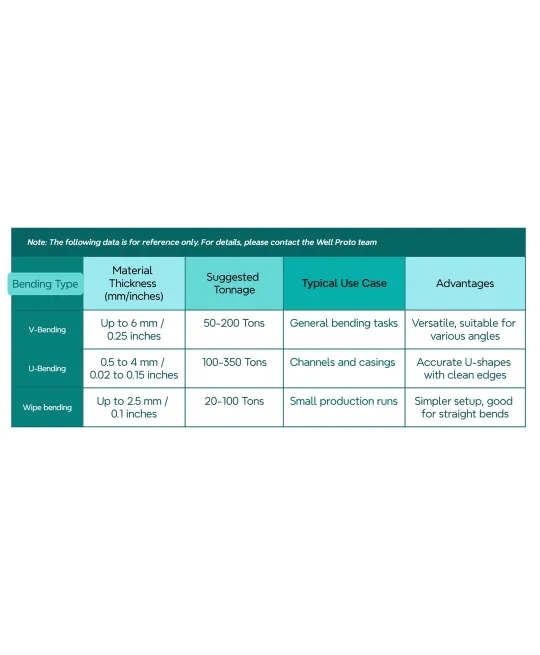

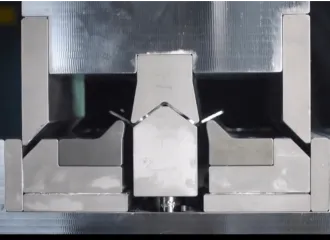

The most common bending method at Well Proto is V-bending which involves pressing the sheet metal into a V-shaped die

Next, we have U-bending, which is similar to V-bending but uses a U-shaped die to create a U-shaped bend in the metal. This method is preferred when U-shaped channels are needed.

Lastly, there is Wipe bending, whereby a ram is used to push the metal against the edge of the die to create the bend. This technique is often used for smaller production runs and can be performed with simple setups.

What is Forming?

Forming is the process of using mechanical force to cause plastic deformation of a material to acquire the desired shape.

Forming can be either cold forming (carried out below the recrystallization temperature of the material) or hot forming (above the recrystallization temperature).

The forming process includes various techniques such as stamping, forging, extrusion, rolling, deep drawing, and several others.

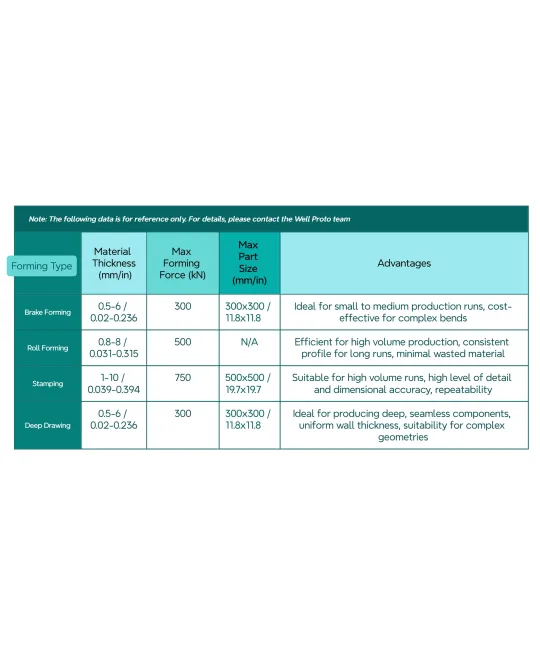

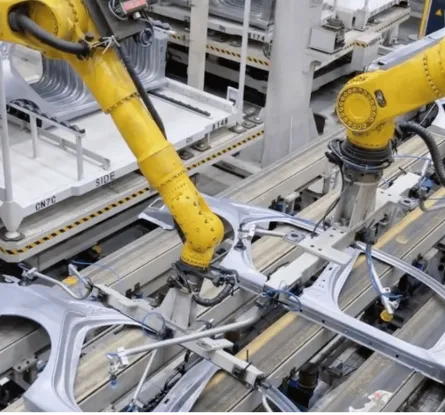

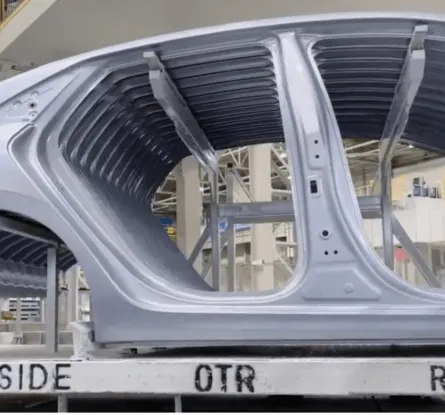

Four Forming Types at Well Proto

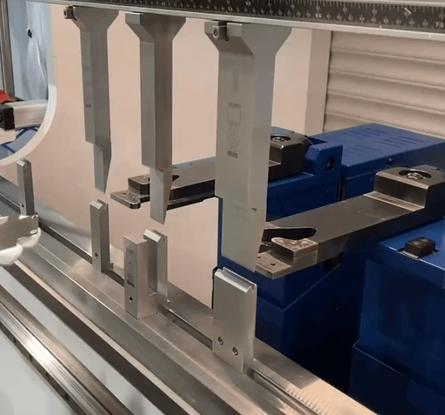

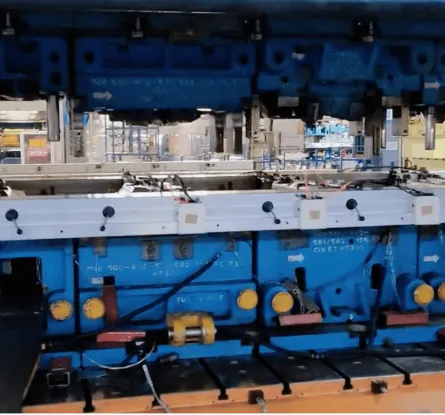

Press Brake Forming: Utilizing press brakes with varying tonnages, we can bend and fold metal sheets with precision, handling a wide range of material thicknesses and sizes.

Roll Forming: Perfect for creating long lengths of complex cross-sections; this method is efficient for large production runs.

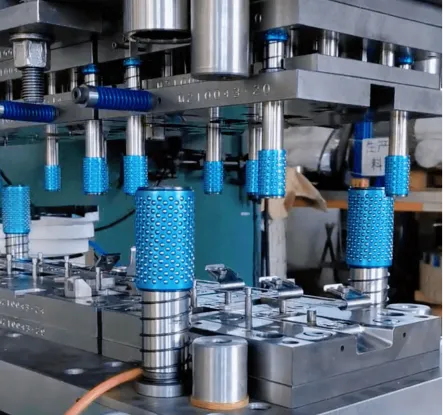

Stamping and Deep Drawing: For parts requiring complex 3D shapes, our stamping and deep drawing services offer an effective solution.

Key aspects of Bending&Forming

Flexibility in Design

Allowed for a wide range of shapes and designs from a single piece of metal, providing greater design flexibility.

Speed and Efficiency

Bending and forming can be quick processes, suitable for both short and long production runs.

Strength and Integrity

Formed parts maintain the strength of the original material, as there is no material removed during the process.

_9dafb.png)

Don’t miss out on these amazing services below!