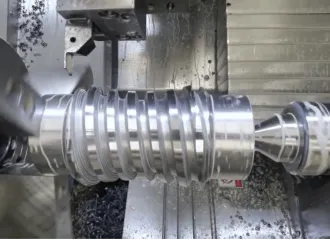

CNC Turning

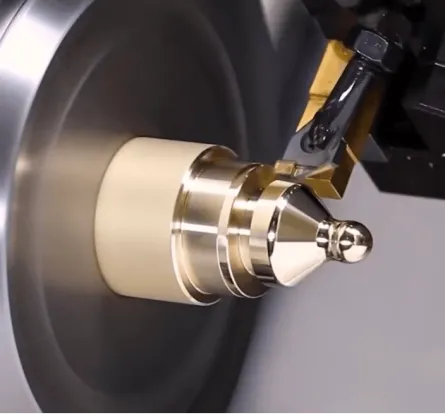

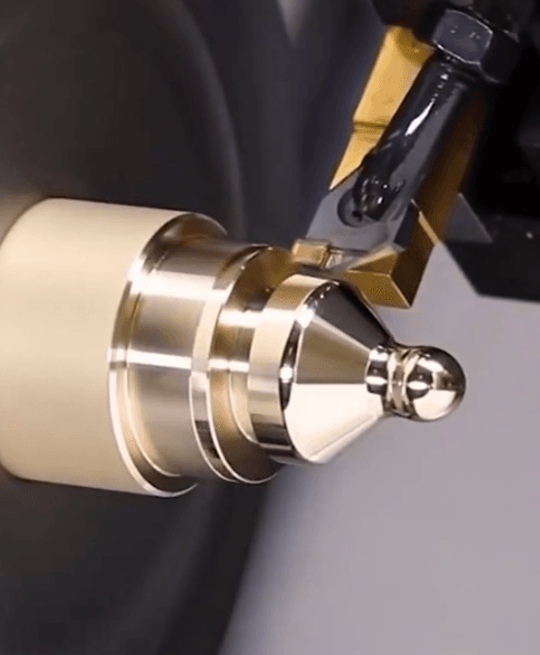

Well Proto state-of-the-art CNC turning centers are capable of creating high-quality cylindrical parts by rotating the workpiece and using a cutting tool to shape the material to your specifications and your precise manufacturing needs

--Certificate : ●ISO9001:2015 ●IATF16949:2016

--All uploads are secure and confidential.

What is CNC Turning?

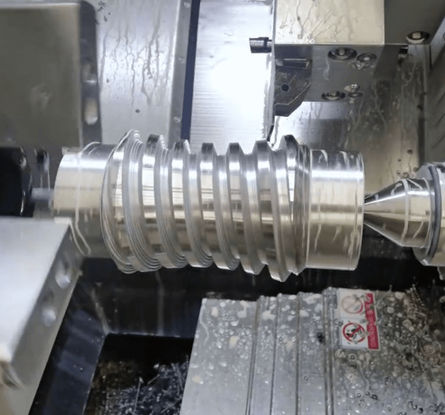

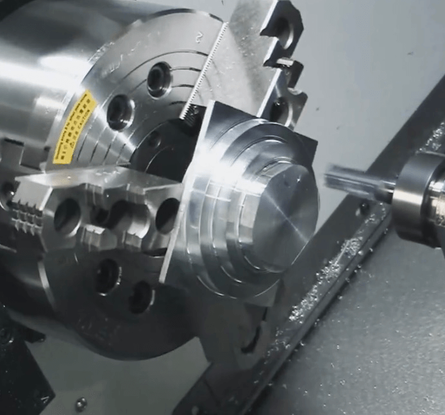

CNC turning is a manufacturing process in which bars of material are held in a chuck and rotated while a tool is fed to the piece to remove material to create the desired shape.

CNC stands for Computer Numerical Control, which means that the machine operation is controlled by a computer.

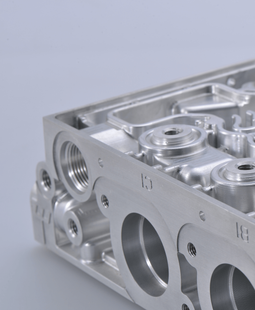

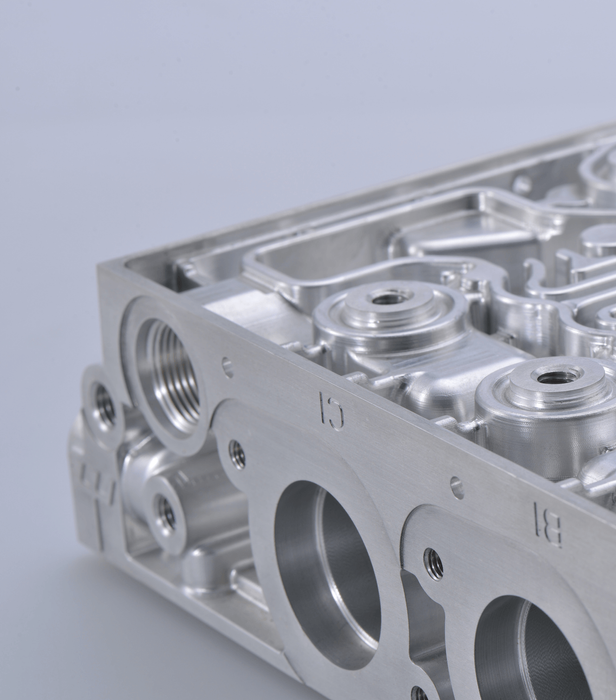

Turning can be performed on the external surface of the part as well as internally (boring). The turning process can produce various shapes such as plain, taper, contour, fillet, and radius profiles plus threaded surfaces.

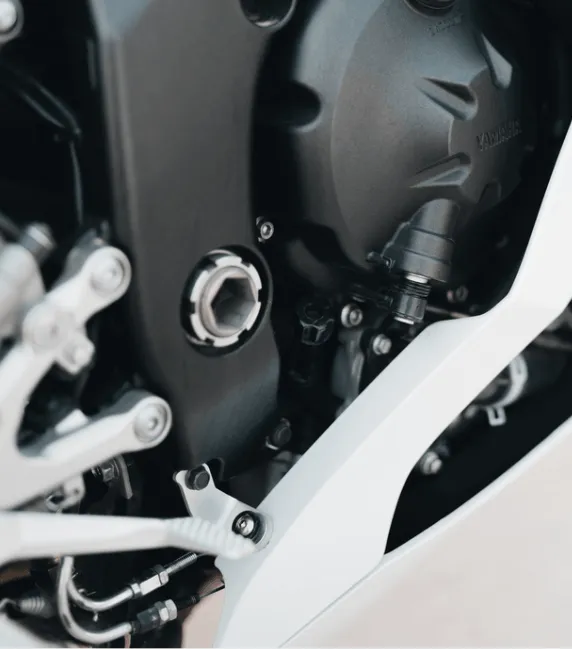

Multi-Material CNC Turning at Well Proto

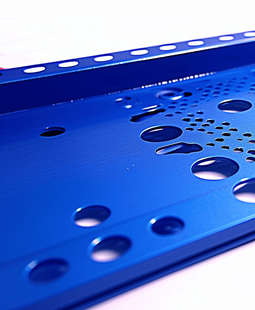

Our modern CNC turning machines can handle a wide range of materials, including metals such as aluminum, brass, steel, stainless steel, and titanium, as well as various plastics.

With our multi-axis CNC lathes, we can perform numerous operations like boring, drilling, threading, and even complex contours, all on the same machine for efficiency and precision.

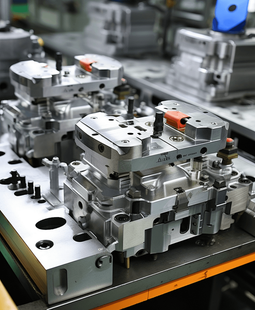

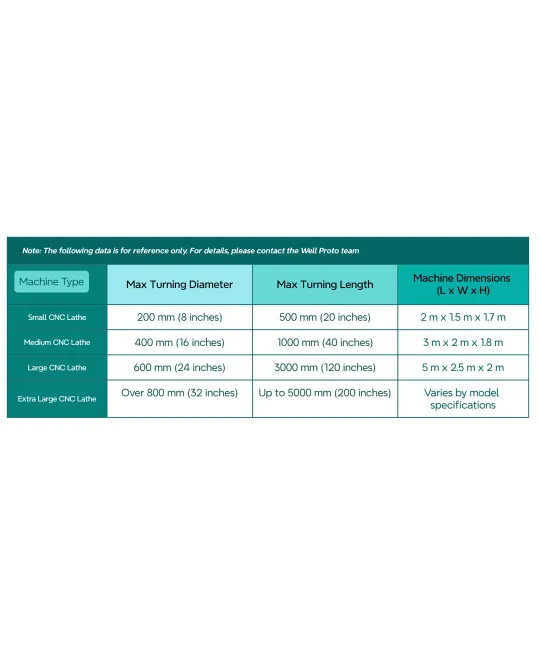

Machines Types at Well Proto

At Well Proto, our diverse array of CNC lathes is designed to cater to the precise tooling and component needs across various industries, experience the compact might of our varied small to mid-sized CNC lathes, designed for nimbleness and precision.

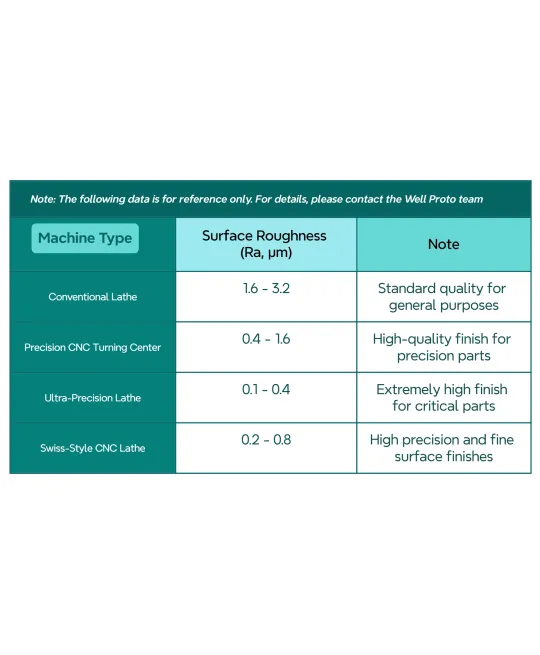

Surface Finish Options for Turned Parts

Components produced through turning generally exhibit a highly polished finish. This is particularly evident on the round surfaces, where lathing results in a noticeably finer surface than milling.

Thus, for parts that are suited to both processes, the choice of machining method should take into account the desired surface texture.

For features such as flats and slots that are created using active tooling, tool marks may remain visible on the surface.

CNC turning Surface Roughness

Surface roughness is influenced not only by the machine but also by the choice of tooling, material properties, and machining parameters including speed, feed rate, and depth of cut.

Well Proto operators can optimize these factors to minimize imperfections and to enhance the part’s surface quality.

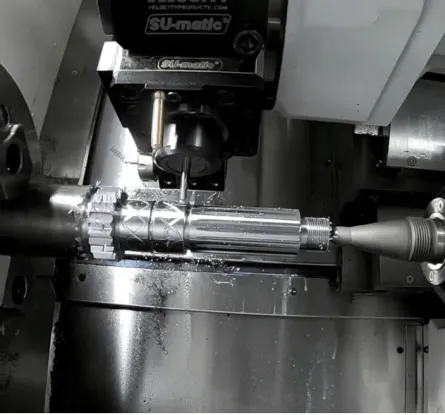

At Well Proto, the Swiss-style CNC Lathes in our arsenal can create surfaces with a Ra of 0.2 to 0.8 µm, offering impressive versatility for intricate and precision-required parts.

Key Aspects of CNC Turning

Complexity and Detail

Advanced CNC machines can perform additional operations like drilling, boring, or threading in one single setup, thus reducing the need for multiple machines.

Reduced Waste

Due to the precision of CNC turning, material waste is minimized. The machine uses the exact amount of material needed to craft the part, contributing to both cost savings and sustainability efforts.

Repeatability

CNC lathes can produce thousands of identical parts without variation, which is critical for industries requiring high standards and consistency like automotive, aerospace, and medical equipment.

Don’t miss out on these amazing services below!