Laser Cutting

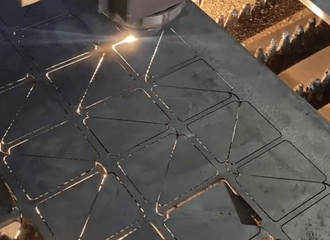

Well Proto's machines are capable of intricate cuts and etchings with an extraordinary level of detail, making them perfect for both prototyping and full-scale production runs

--Certificate : ●ISO9001:2015 ●IATF16949:2016

--All uploads are secure and confidential.

What is Laser Cutting?

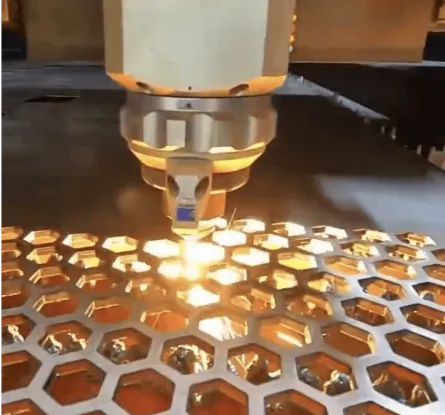

Laser cutting is a technology that uses a powerful laser to cut and shape materials like metal, plastic, or wood. It’s a precise method where a computer guides the laser beam to follow the desired pattern.

The laser quickly burns or melts through the material, resulting in clean and accurate cuts. It’s commonly used in manufacturing for making parts and in arts for creating detailed designs.

Laser cutting works by directing the output of a high-power laser most commonly through optics.

Orientation and Positioning

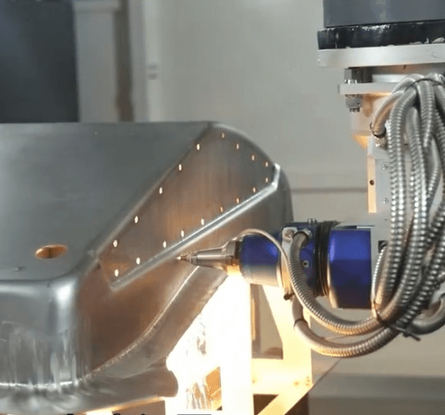

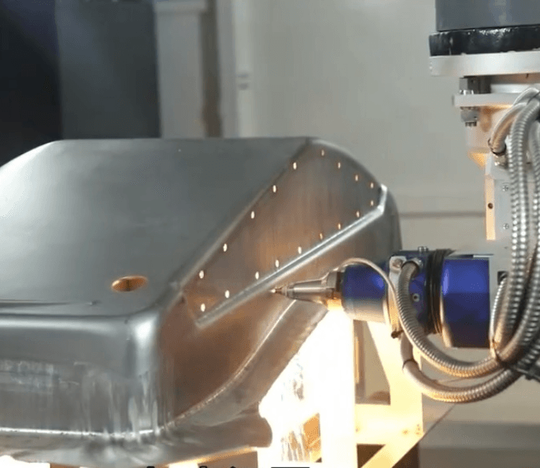

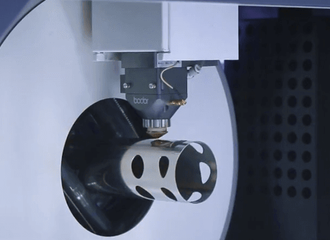

Well Proto's laser cutting primarily involves 2D operations on the X and Y axes for flat part fabrication.

However, with advanced setups and 3D cutting technology, it is capable of executing 3D cuts, including beveled edges and intricate shapes, allowing for complex part preparation.

Well Proto's laser cutters produce an extensive variety of precise shapes with tight tolerances, necessary for detailed assemblies, including everything from basic geometric figures to complex mechanical components and decorative patterns.

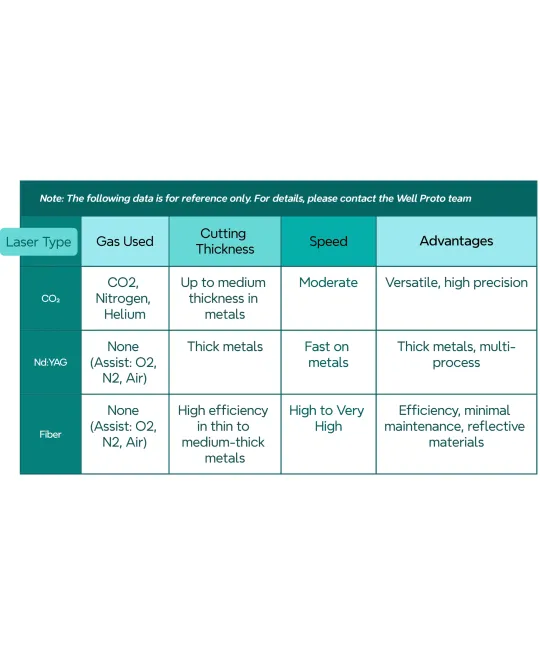

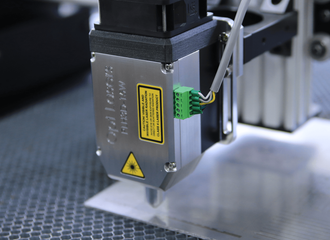

Three Laser Types at Well Proto

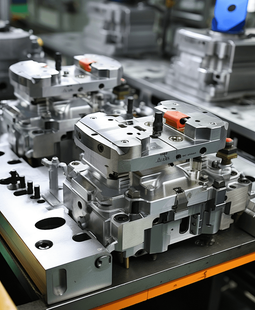

Laser cutting at Well Proto is a highly accurate method to sculpt designs from various materials, guided seamlessly by CAD files.

Our facility boasts state-of-the-art machinery comprising three primary types of lasers prevalent in the industry: CO2 lasers, neodymium (Nd) lasers, and yttrium-aluminum-garnet (Nd:YAG) lasers.

Our CO2 lasers are routinely employed for cutting, boring, and engraving. While both Nd and Nd:YAG lasers possess similar styles and functionalities, they are utilized distinctly within Well Proto to cater to different specialized tasks.

Experience Superior Thickness and Finishing

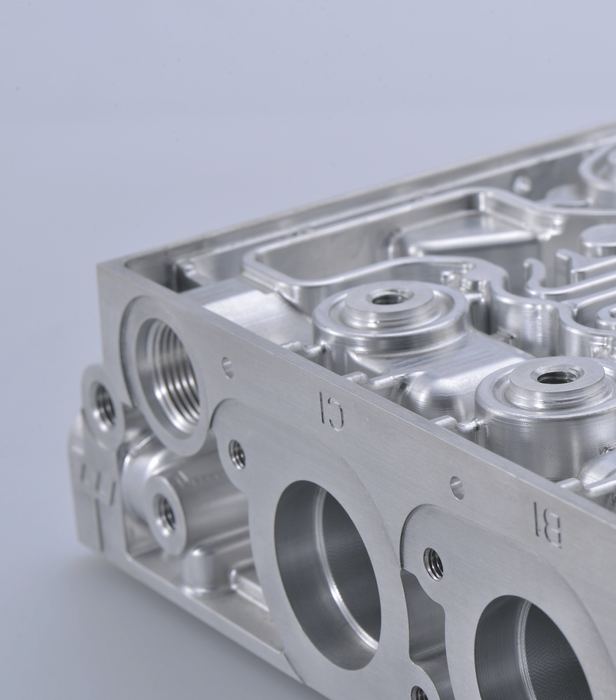

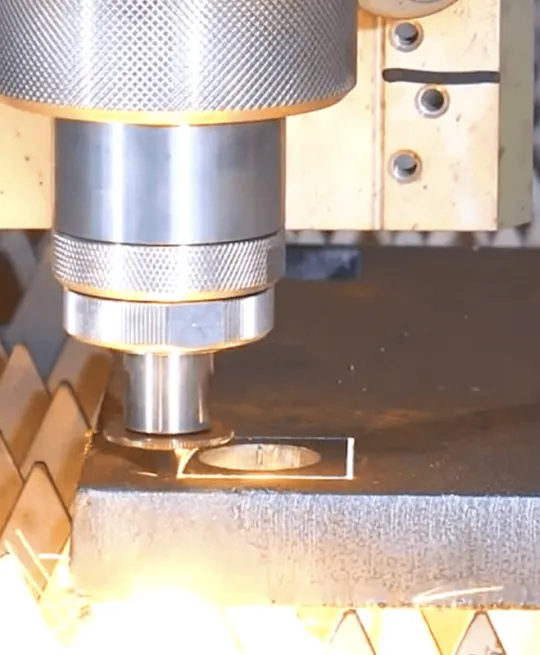

Well Proto's state-of-the-art lasers deliver consistently clean, accurate cuts across a variety of materials, from thin sheets to thick plates.

Our cutting process emphasizes quality, sharply reducing thermal damage to edges, enhancing the final product with a superior finish without compromising intricate designs or precise tolerances.

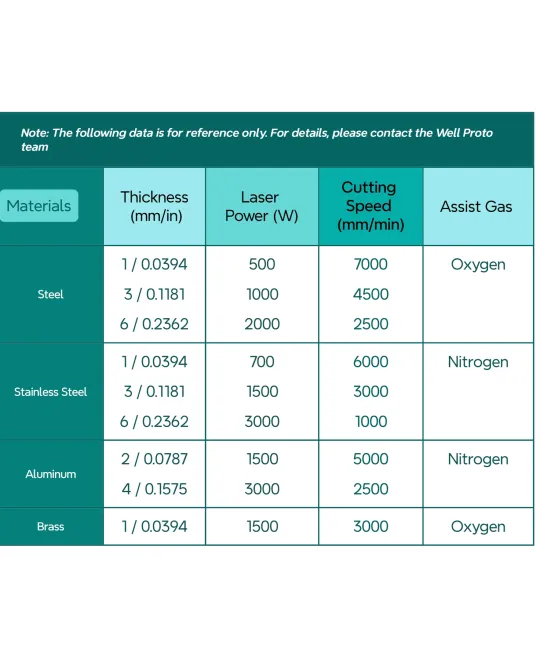

Versatile Material Compatibility

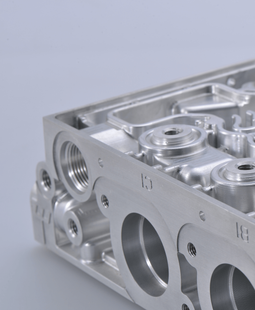

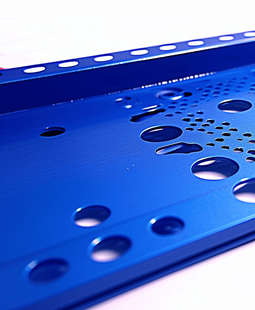

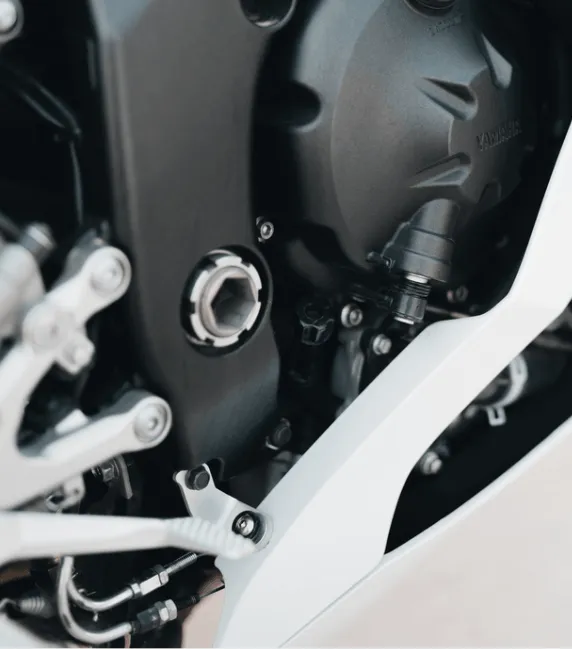

Our workshop is equipped with advanced CNC laser cutting machines that can handle a wide range of materials including steel, stainless steel, aluminum, copper, brass, and various plastics.

These machines are capable of intricate cuts and etchings with an extraordinary level of detail, making them perfect for both prototyping and full-scale production runs.

Key Aspects of Laser Cutting

Quality of Cut

Edges are clean and have a smooth finish, often requiring no further processing.

Speed

It is typically faster than traditional mechanical cutting methods, especially for complex cuts or designs, because it’s controlled by CNC machines.

Low Heat Output

Minimizes the heat-affected zone and reduces material distortion.

Don’t miss out on these amazing services below!