Casting

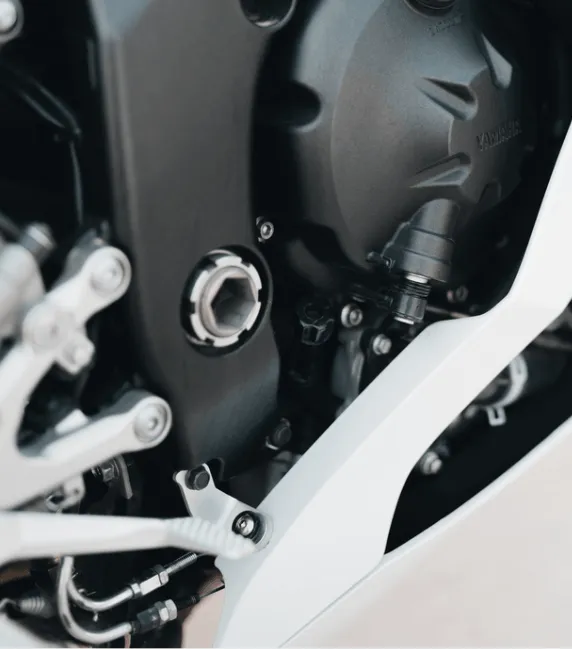

Familiar with the production, manufacturing, and protection of various casting processes, providing high-quality parts.

--Certificate : ●ISO9001:2015 ●IATF16949:2016

--All uploads are secure and confidential.

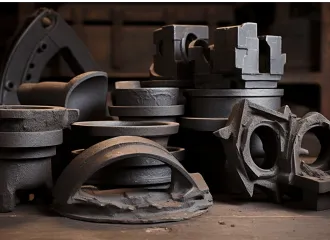

What is Casting?

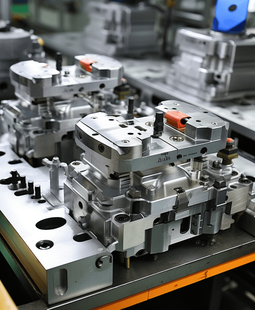

Casting is a widely used manufacturing method due to its ability to produce detailed and complex shapes, as well as its cost-effectiveness for large-scale production. There are various types of casting processes, including sand casting, investment casting, die casting, and more, each suited to different materials and production requirements.

During the casting process, the molten material is poured into a mold, where it solidifies and takes on the shape of the mold cavity. Once the material has cooled and solidified, the mold is removed, leaving behind the finished product.

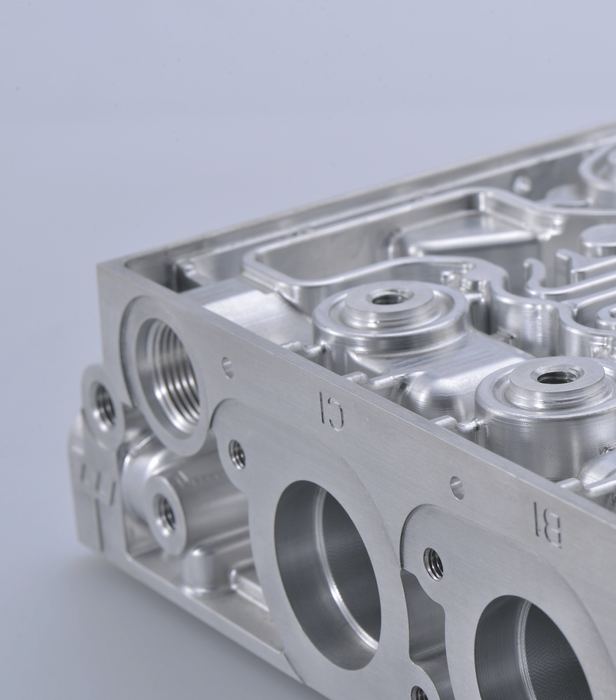

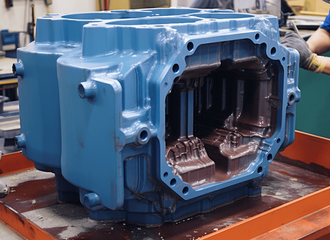

Ensuring Quality in Casted Components

After the demolding process, Well Proto conducts a series of meticulous inspections on casted components to maintain stringent quality standards.

These comprehensive inspections involve precise measurement of dimensions to verify accuracy, thorough evaluation of surface roughness to ensure a smooth finish, advanced defect detection techniques to eliminate imperfections, in-depth analysis of chemical composition for material integrity, and rigorous testing of mechanical properties to guarantee structural robustness.

Through these rigorous inspections, we ensure that the components not only meet but exceed the required industry standards and specifications, thus ensuring exceptional quality and reliability.

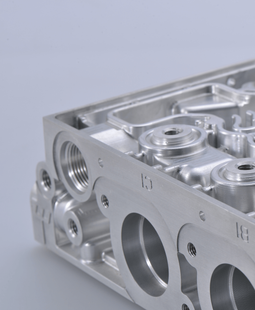

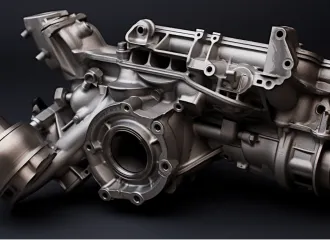

Different Casting Techniques at Well Proto

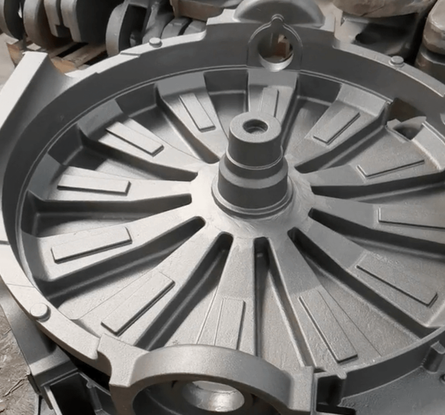

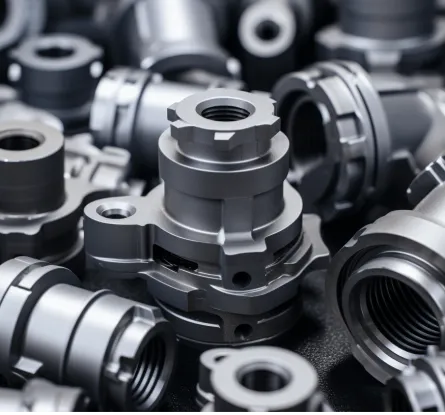

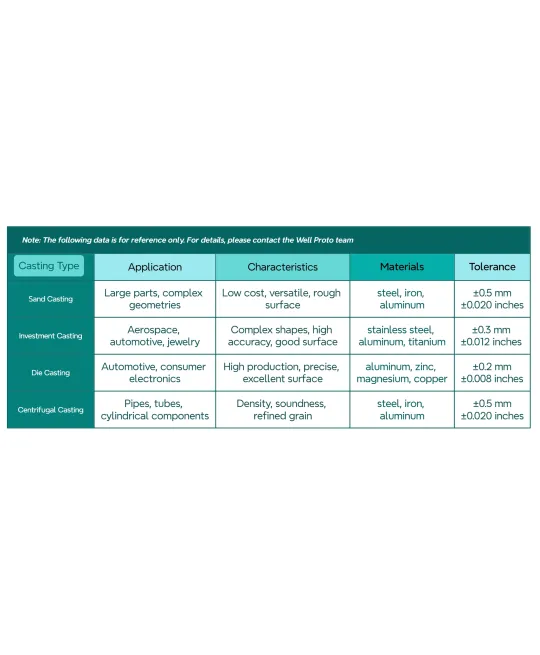

Well Proto specializes in four types of casting processes: sand casting, investment casting, die casting, and centrifugal casting. Sand casting is versatile and suitable for producing large parts with rough surface finishes, while investment casting excels at creating intricate and high-precision components with smooth surface finishes.

Die casting is ideal for high-volume production of thin-walled parts with excellent dimensional accuracy, and centrifugal casting is used for cylindrical components requiring refined grain structures. Each process has its own applications, suitable materials, surface finishes, and tolerances, allowing Well Proto to provide tailored solutions to meet the diverse needs of our clients.

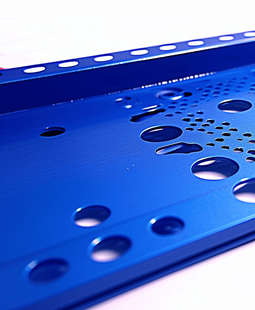

Well Proto’s Protective Practices

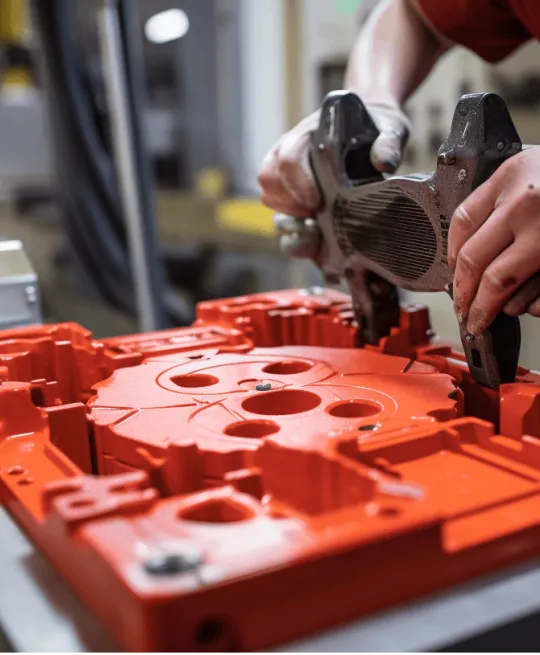

Well Proto ensures the protection of casting molds through proactive maintenance and care.

This includes implementing proper storage procedures to prevent damage, regular cleaning and lubrication to maintain optimal functionality, and timely repairs to address any wear and tear. Additionally, we incorporate effective corrosion prevention measures and employ advanced coatings to extend the lifespan of the molds.

By prioritizing these protective practices, we safeguard the integrity and longevity of our casting molds, ultimately ensuring consistent high-quality production.

Key Aspects of Casting

Complex shapes

Casting can create complex shapes that are hard or costly to make with other methods.

Material properties

It is a necessary process for manufacturing parts from materials with poor machinability.

Cost-effective

Casting allows for the economical production of large parts, reducing manufacturing costs.

Don’t miss out on these amazing services below!