CNC Milling

Well Proto, where state-of-the-art technology meets precision and craftsmanship in the field of CNC milling. Our commitment is to deliver premium, customized machined parts that fit your specific project requirements

--Certificate : ●ISO9001:2015 ●IATF16949:2016

--All uploads are secure and confidential

What is CNC Milling?

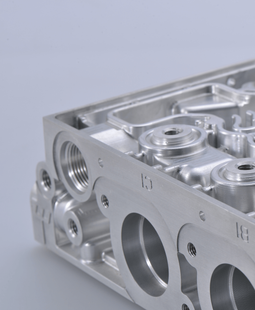

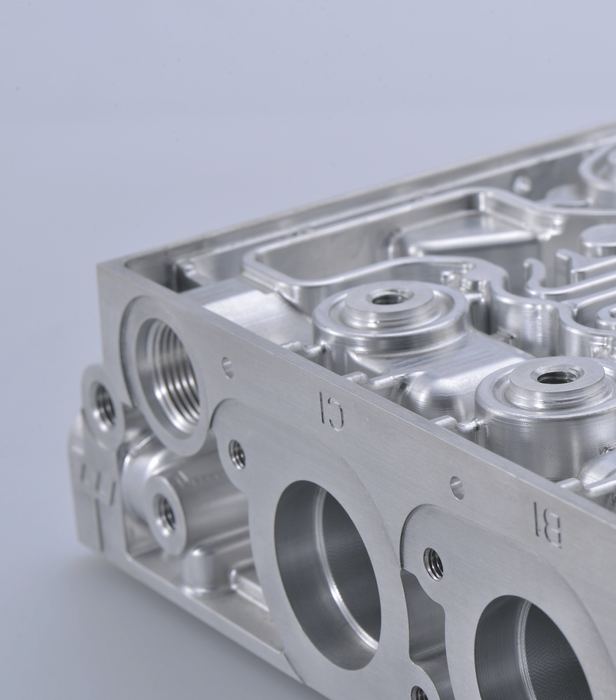

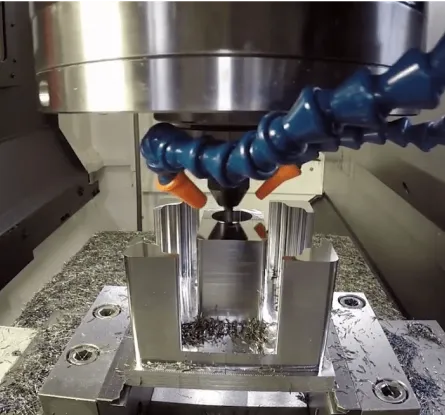

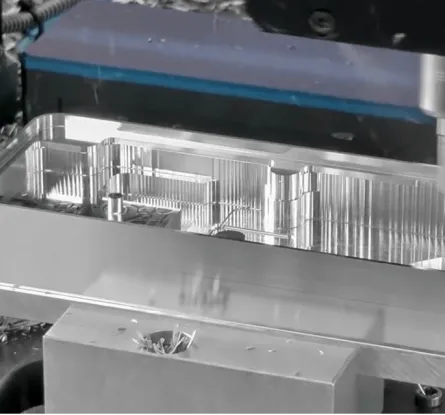

CNC milling is a machining process that utilizes computer-controlled, rotating multi-point cutting tools (such as end mills and drill bits) to progressively remove material from a workpiece.

The CNC in CNC milling stands for Computer Numerical Control, which indicates that the milling machine is operated by a computer that precisely controls the movement and actions of the cutting tools.

In the CNC milling process, a piece of material (metal, plastic, wood, composite, etc.) is secured to a work table using clamps or a vice.

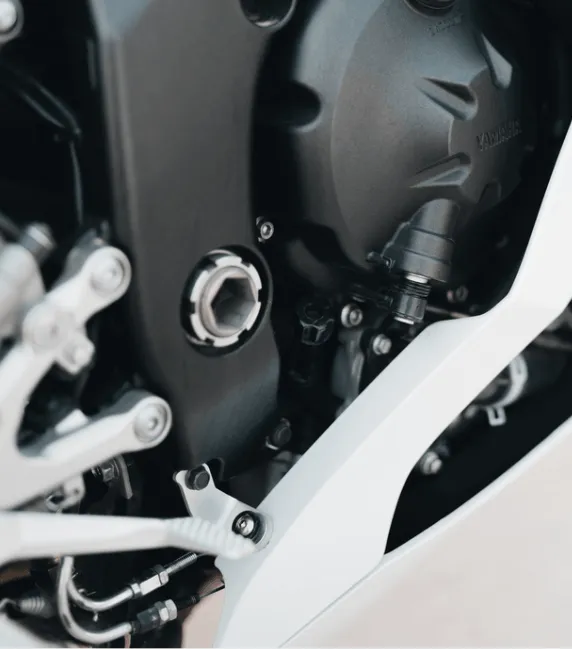

Precision Across Dimensions at Well Proto

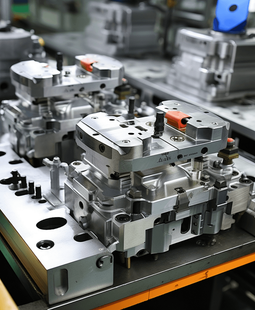

Well Proto high-precision 3-axis, 4-axis, and 5-axis CNC machining centers enable us to produce components with intricate shapes, deep cuts, and complex angles.

The additional axes allow for simultaneous movement and rotation, facilitating the manufacturing of very complex parts.

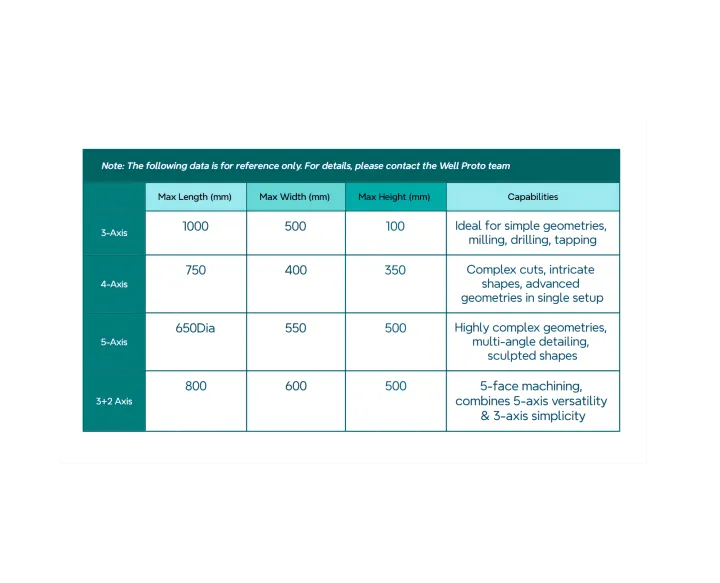

Well Proto 'CNC milling machine dimensions(mm)

Well Proto’s CNC milling machines boast a size range perfect for intricate small parts and large-scale projects alike.

With models designed for precision across various dimensions, they ensure quality and accuracy for any manufacturing demand.

Whether handling compact components or sizable productions, Well Proto machines deliver consistent, precise results tailored to client specifications.

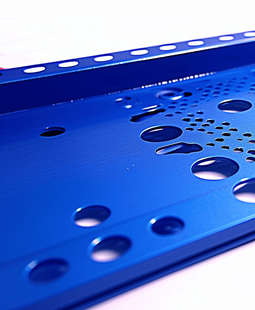

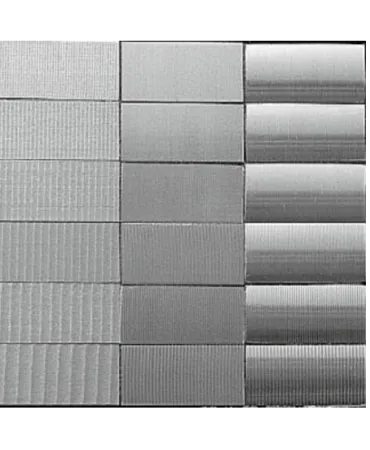

CNC Milling surface finishing at Well Proto

The surface finish of a part will often depend on the machining process, the material being used, the type of cutting tools, as well as the machine’s capabilities.

Here is a general guideline on the surface finishes we can provide with our different CNC machines.

_21624.png)

Precision&Tolerances

At Well Proto, we understand the critical importance of precision and tolerance in the manufacturing of parts.

Our equipment is state-of-the-art, and our team is highly skilled, enabling us to offer tight tolerances and high precision across a range of machining configurations.

The tolerances we can achieve depend on the axis configuration of our CNC machines, as well as on the material being machined and the geometry of the part. Left is a table illustrating the general tolerances typically attainable with our CNC equipment:

Key Aspects of CNC Milling

Flexibility

A wide range of materials can be milled, and the process can create complex shapes and features that would be difficult or impossible to achieve with manual machining.

Repeatability

Once programmed, CNC mills can make the same part countless times with little variation.

High Speed & Efficiency

CNC milling machines can operate at high speeds, making them much more productive than manual machines.

Don’t miss out on these amazing services below!