Reducing Manufacturing Costs with Smart CNC Solutions

By:

Well Proto Team

On

10/12/2022Summary:

Learn how smart CNC strategies can streamline production and cut costs. We’ll explore efficient software for toolpath optimization, ideal material and finish selection. Also, discover essential tips for reducing waste and refining production planning to boost your manufacturing economy.

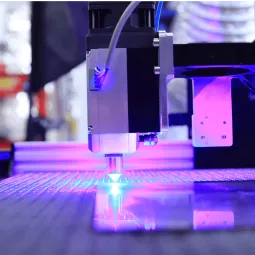

Toolpath Optimization with Advanced Software

One of the most effective ways to reduce manufacturing costs is by utilizing advanced software for CNC toolpath optimization. Complex parts require precise tool movements, and any inefficiency in the toolpath can lead to wasted time and resources.

By integrating state-of-the-art software that intelligently calculates the most efficient toolpath, Well Proto has achieved substantial reductions in cycle times. Not only does this reduce the wear and tear on our machinery, but it also translates to faster production rates and lower energy consumption.

Sophisticated algorithms ensure minimal tool changes and adapt to the unique geometry of each piece, resulting in a smoother machining process and impeccable finish quality.

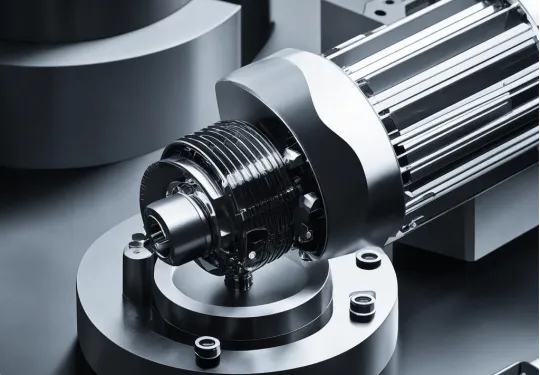

Selecting the Right Materials and Finishes

The cost of raw materials can significantly impact the overall expenses of manufacturing. At Well Proto, we help our clients choose the ideal material for their projects, balancing quality and cost.

With a profound understanding of material properties and their behavior during machining, we can make recommendations that align with both budget and performance requirements. Similarly, selecting the most appropriate finish impacts both the aesthetic appeal and functional performance of the final product.

By considering factors such as corrosion resistance, surface roughness, and cosmetic value, we're able to provide finishes that enhance product longevity and customer satisfaction, while keeping costs in check.

Reducing Waste and Refining Production Planning

Waste reduction is a key aspect of economical manufacturing. Implementing smart CNC solutions, Well Proto has refined its production planning to significantly minimize excess material use and streamline the fabrication process.

By using precision machining and adhering to lean manufacturing principles, we ensure that every piece of material is utilized to its fullest potential, thereby reducing physical waste and associated costs.