A Brief Description of Five Axis CNC Machining Impeller

On

15/03/2024Summary:

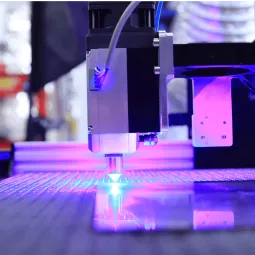

When we start the discussion on CNC 5-axis machining with impeller parts as our focus, we are essentially exploring an advanced technology that significantly boosts manufacturing efficiency and part quality. The machining of impeller parts particularly showcases the importance and advantages of CNC 5-axis machining technology, as impellers often comprise complex geometries and details, posing high demands on the machining technology.

Let's delve deeper into this process through several key aspects:

The Importance of Design and Preparation:

1. 3D Modeling: This step is foundational to the entire machining process, ensuring the precise transition of the design into the machining stage. For complex parts like impellers, accurate 3D models are essential for high-quality machining.

2. CAM Programming: Effective CAM programming is directly linked to the efficiency and quality of machining. For impellers, rational planning of tool paths, selection of tools, and setting of machining parameters are crucial to ensure the quality of the machined part.

The Manifestation of Process Features:

1. Capability to Machine Complex Geometries: The complex surfaces and details of impellers require the machining process to precisely control the tool's movement in multiple directions, a capability provided by CNC 5-axis machining technology.

2. Requirements for High Precision and Smoothness: The performance of impellers greatly depends on their precision and surface smoothness, achievable through CNC 5-axis machining, ensuring efficient operation and long-term stability of impellers.

3. Reduction in Fixture and Setup Time: By reducing the need for repositioning impellers during machini

specific Application of Machining Steps:

1. From Roughing to Finishing**: This series of steps reflects the transition from rough contours to fine details, each being crucial for the final performance of the impeller.

2. Material Characteristics, Cooling Lubrication, and Tool Path Optimization: Tailored to the unique material and shape characteristics of impellers, these considerations ensure the efficiency and quality of the machining process.

Conclusion:

CNC 5-axis machining technology offers an ideal solution for producing complex parts such as impellers. By comprehensively considering aspects like design, preparation, process features, and steps, CNC 5-axis machining can achieve efficient, high-quality production of high-precision parts. This not only optimizes the production process but also enhances the performance and reliability of the final product, meeting the stringent requirements of modern industry for high-performance components.