Mold Manufacturing and CNC Machining – The Core of Precision Mold Production

By:

Well Proto Team

On

24/02/2024Summary:

The Importance of Mold Manufacturing Mold manufacturing plays a crucial role in mass production processes such as plastic injection molding, die casting, and stamping. The quality of the mold directly affects the precision and appearance of the final product. To ensure the highest quality, CNC machining is often used to achieve the tight tolerances and complex geometries required for molds.

The Importance of Mold Manufacturing

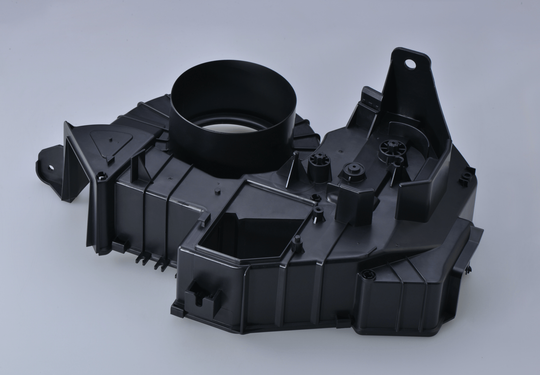

Mold manufacturing is a key component in mass production, especially in industries like plastic injection molding, die-casting, and stamping. The quality of molds directly impacts the quality and precision of the final products. CNC machining is widely used in mold manufacturing to ensure the high precision required for producing complex mold parts.

Molds are used to form raw materials into desired shapes through processes like injection molding or casting. Whether the mold is for plastic products, metal parts, or composite components, the precision and qualit

CNC Machining in Mold Manufacturing

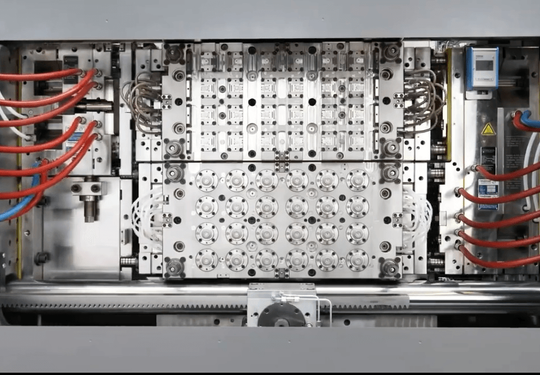

Precision Cutting: CNC machines can achieve the micron-level precision necessary for the production of high-quality molds. This is particularly important for industries that demand intricate details and flawless surfaces, such as automotive and consumer electronics.

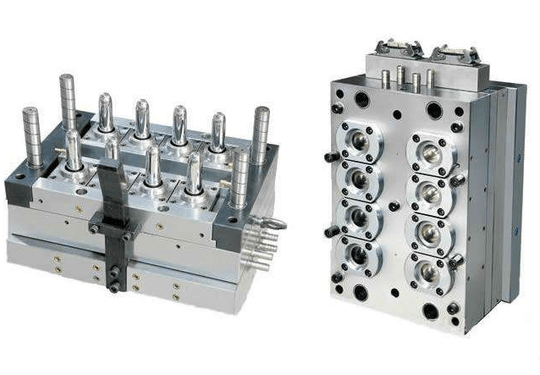

Complex Geometries: CNC machining allows for the creation of intricate, detailed features in molds, which would be nearly impossible to produce using traditional methods. This is particularly beneficial when manufacturing multi-cavity molds or molds with complex cooling channels.

Rapid Prototyping: Speed is often critical in mold manufacturing. CNC machining can produce mold prototypes rapidly, enabling manufacturers to quickly test designs and make adjustments as necessary before moving into full-scale production.

WellProto’s Mold Manufacturing Expertise

At WellProto, we provide custom CNC machining services for mold manufacturing, ensuring that the molds we produce meet the highest standards of precision and quality. Our team has extensive experience working with industries such as automotive, consumer electronics, and medical devices.

Custom Mold Solutions: We offer customized solutions for a wide range of mold types, including injection molds, die-casting molds, and stamping molds. Our team works closely with clients to ensure their molds are produced with the highest accuracy and durability.

Advanced CNC Capabilities: With our 5-axis CNC machining technology, we are capable of producing highly detailed and complex mold components, ensuring that each part is crafted with precision.

Efficient Production: We understand the importance of fast production cycles. WellProto delivers high-quality molds with quick turnaround times, ensuring that clients can move forward with manufacturing as soon as possible.

WellProto’s Mold Manufacturing Advantage

High-Precision Molds: We specialize in the production of highly precise and complex molds that meet the strictest industry standards.

Advanced Technology: Our CNC machining services utilize the latest in mold-making technology, ensuring that every mold we produce is accurate, reliable, and efficient.

Fast Turnaround: WellProto ensures that molds are produced quickly without sacrificing quality, so you can meet your production deadlines.